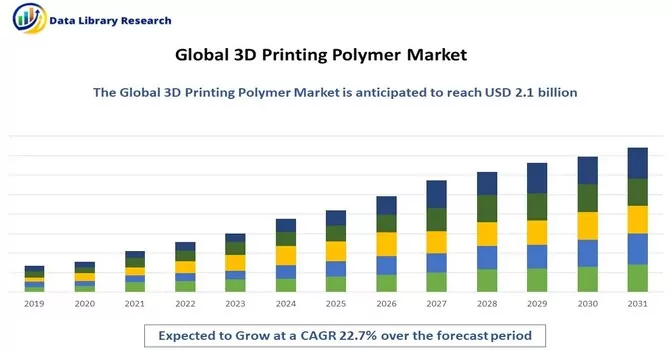

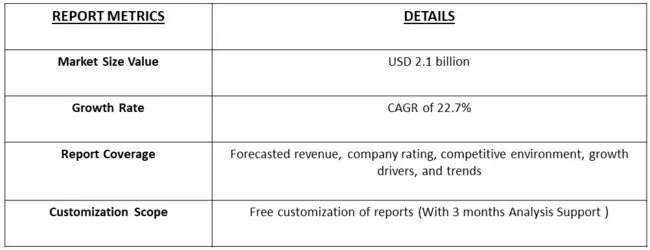

The 3D printing plastics market is estimated at USD 2.1 billion in 2024 and is projected to register a CAGR of 22.7% from 2024 to 2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

The 3D printing polymer material market has witnessed significant growth in recent years, driven by the expanding applications of 3D printing across various industries such as aerospace, automotive, healthcare, and consumer goods. 3D printing, also known as additive manufacturing, enables the fabrication of complex geometries and customized products with reduced material waste and shorter lead times compared to traditional manufacturing methods. Polymer materials, including thermoplastics, photopolymers, and composite materials, are widely used in 3D printing due to their versatility, affordability, and ease of processing.

Moreover, advancements in polymer chemistry and additive manufacturing technologies have led to the development of high-performance polymers with enhanced mechanical properties, thermal stability, and chemical resistance, further fueling market growth. Additionally, the growing adoption of 3D printing in prototyping, product development, and rapid manufacturing applications is driving the demand for polymer materials, as manufacturers seek to leverage the benefits of additive manufacturing to streamline production processes and accelerate innovation. Furthermore, the rising demand for personalized and on-demand manufacturing solutions, coupled with the increasing availability of 3D printing systems and materials, is expected to drive continued growth in the 3D printing polymer material market. The growth of the 3D printing polymer material market is propelled by several key factors. Firstly, the expanding applications of 3D printing across various industries such as aerospace, automotive, healthcare, and consumer goods are driving the demand for polymer materials. These materials offer versatility, affordability, and ease of processing, making them suitable for a wide range of applications. Secondly, advancements in polymer chemistry and additive manufacturing technologies have led to the development of high-performance polymers with enhanced mechanical properties, thermal stability, and chemical resistance. This has broadened the scope of applications for 3D printing polymer materials, particularly in industries requiring durable and functional end-use parts. Thirdly, the growing adoption of 3D printing in prototyping, product development, and rapid manufacturing applications is fueling demand for polymer materials. Manufacturers are increasingly turning to additive manufacturing to streamline production processes, reduce lead times, and accelerate innovation. Additionally, the rising demand for personalized and on-demand manufacturing solutions is driving the need for a diverse range of polymer materials to meet specific customer requirements. Overall, these factors are driving the growth of the 3D printing polymer material market, with continued expansion expected in the coming years.

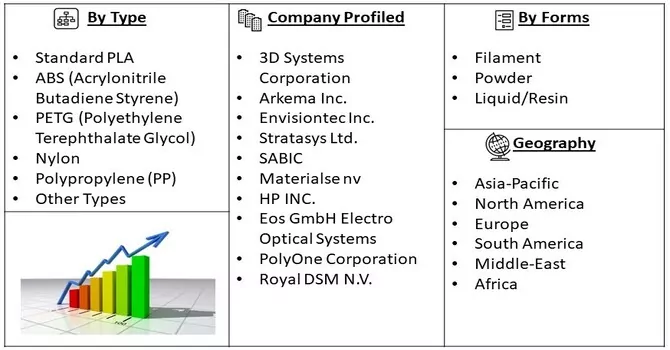

Market Segmentation: Market segmentation for the 3D printing polymer market can be based on various factors such as Type (Standard PLA, ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), Nylon, Polypropylene (PP), Other Types), Forms (Filament, Powder, and Liquid/Resin) and Geography (North America, Europe, Asia-Pacific, Middle East and Africa, and South America). The report offers the value (in USD million) for the above segments.

For Detailed Market Segmentation - Download Free Sample PDF

The 3D printing polymer material market is witnessing several notable trends that are shaping its landscape. Firstly, there is a growing emphasis on the development of bio-based and sustainable polymer materials to address environmental concerns and reduce dependence on fossil fuels. Companies are investing in research and development to create polymers derived from renewable sources such as plant-based feedstocks or recycled materials. Secondly, there is an increasing demand for high-performance polymers with enhanced properties such as strength, flexibility, and heat resistance to meet the requirements of diverse applications. This trend is driven by the expanding use of 3D printing in industries such as aerospace, automotive, and medical, where stringent performance standards are essential. Thirdly, there is a shift towards the development of multi-functional and composite polymer materials that offer a combination of properties to cater to complex application needs. These materials often incorporate additives or fillers to impart additional functionalities such as conductivity, antimicrobial properties, or flame retardancy. Fourthly, advancements in 3D printing technologies, such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM), are enabling the use of a wider range of polymer materials and expanding the capabilities of additive manufacturing. Lastly, there is a growing trend towards customization and digitalization in manufacturing, driving the demand for tailored polymer materials and digital supply chain solutions. Overall, these trends are expected to continue shaping the 3D printing polymer material market, driving innovation and expanding the range of applications in various industries.

Market Drivers:

Technological Advancements:

Continuous advancements in 3D printing technologies, such as improved printing resolution, faster printing speeds, and expanded material compatibility, are driving the growth of the market. These advancements are enabling manufacturers to produce complex geometries, intricate designs, and functional prototypes with greater accuracy and efficiency, thereby increasing the demand for 3D printing polymer materials.

Increasing Adoption Across Industries:

The growing adoption of 3D printing technology across various industries, including aerospace, automotive, healthcare, consumer goods, and electronics, is fueling the demand for polymer materials. Industries are increasingly leveraging 3D printing for prototyping, tooling, and end-use part production due to its cost-effectiveness, design flexibility, and shorter lead times. As a result, there is a rising need for a diverse range of polymer materials that can meet the specific requirements of different applications and industries.

Market Restraints:

One of the significant restraints for the 3D printing polymer material market is the limited material properties and performance characteristics of currently available polymer materials. While advancements in 3D printing technology have expanded the range of materials compatible with additive manufacturing processes, many polymers still lack the mechanical strength, durability, and heat resistance required for demanding applications. Additionally, some polymer materials may exhibit undesirable properties such as warping, shrinkage, or poor surface finish during the printing process, limiting their usability for certain applications. Addressing these limitations and developing new polymer formulations with enhanced properties poses a challenge for material manufacturers and hampers the widespread adoption of 3D printing in industries requiring high-performance components. Moreover, concerns regarding material quality, consistency, and traceability also contribute to market restraints, as manufacturers seek reliable and standardized materials for their additive manufacturing processes.

The COVID-19 pandemic has had a mixed impact on the 3D printing polymer material market. While the initial disruptions in global supply chains and manufacturing operations led to temporary slowdowns in production and demand, the pandemic also highlighted the agility and versatility of additive manufacturing technologies. As traditional supply chains faced disruptions and shortages, 3D printing emerged as a viable solution for rapidly producing essential medical supplies, personal protective equipment, and other critical components. This increased adoption of 3D printing for emergency response and medical applications underscored the resilience and flexibility of additive manufacturing, driving awareness and interest in 3D printing polymer materials. Additionally, the pandemic spurred innovation and collaboration within the 3D printing industry, leading to the development of new materials, processes, and applications to address emerging needs. However, economic uncertainties, reduced capital expenditures, and supply chain challenges continue to pose challenges for the 3D printing polymer material market, impacting investment decisions and project timelines. As businesses adapt to the new normal and focus on resilience and efficiency, the long-term impact of COVID-19 on the 3D printing polymer material market remains uncertain.

Segmental Analysis:

ABS (Acrylonitrile Butadiene Styrene) Segment is Expected to Witness Significant Growth Over the Forecast Period

ABS (Acrylonitrile Butadiene Styrene) has become increasingly popular in the 3D printing polymer market due to its excellent mechanical properties, including strength, toughness, and impact resistance, making it ideal for producing durable functional prototypes and end-use parts. Its compatibility with FDM printers, ease of printing, and post-processing capabilities further contribute to its appeal, allowing for smooth finishes and intricate designs. ABS's chemical resistance and wide range of applications across industries such as automotive, electronics, and consumer goods have also contributed to its growing use. Despite some drawbacks like emissions and high printing temperatures, ABS remains a cost-effective and versatile choice for 3D printing enthusiasts and professionals.

Filament Segment is Expected to Witness Significant Growth Over the Forecast Period

The filament segment is a critical component of the 3D printing polymer market, representing a substantial share of the overall industry. Filaments are used in FDM (Fused Deposition Modeling) 3D printers, which are among the most widely used types of 3D printers due to their affordability and ease of use. Filaments are typically made from thermoplastics such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and others, each offering unique properties suitable for different applications. The filament segment has seen significant growth due to several factors. First, the increasing adoption of 3D printing across various industries, including aerospace, automotive, healthcare, and consumer goods, has driven the demand for filaments. These industries use 3D printing for prototyping, customized manufacturing, and production of end-use parts, creating a steady demand for high-quality filaments. Second, advancements in filament technology have led to the development of filaments with enhanced properties, such as improved strength, flexibility, and heat resistance. This has expanded the range of applications for 3D printing, further driving the demand for filaments. Moreover, the growing availability of filaments in a wide range of colors, sizes, and materials has made 3D printing more accessible to hobbyists, artists, and educators, contributing to the segment's growth. Thus, the filament segment is highly competitive, with numerous manufacturers and suppliers offering a wide range of products. Price competition is intense, particularly among manufacturers in regions with lower production costs. As a result, the filament segment is expected to continue its growth trajectory, driven by the increasing adoption of 3D printing across industries, technological advancements in filament materials, and the expanding applications of 3D printing. However, challenges such as the need for recyclable and sustainable filament materials and regulatory issues related to filament disposal may impact the segment's growth in the future.

North America Region is Expected to Witness Significant Growth Over the Forecast Period

North America is a key region in the 3D printing polymer market, accounting for a significant share of the global industry. The region's market growth is driven by several factors, including technological advancements, a strong presence of key players, and a growing demand for 3D printing in various industries. One of the key drivers of the 3D printing polymer market in North America is the region's strong focus on innovation and technology. The presence of leading 3D printing companies, research institutions, and academic centers has fueled the development of new materials, processes, and applications for 3D printing polymers. This has led to the introduction of high-performance polymers with enhanced properties, expanding the market's potential in industries such as aerospace, automotive, healthcare, and consumer goods. Additionally, North America has a robust manufacturing sector, which has embraced 3D printing for rapid prototyping, customized manufacturing, and production of end-use parts. The region's advanced infrastructure and skilled workforce further support the adoption of 3D printing, driving the demand for 3D printing polymers. Moreover, the growing awareness of sustainability and environmental concerns has led to an increased interest in bio-based and recyclable 3D printing polymers in North America. Manufacturers are focusing on developing eco-friendly materials to meet the demand for sustainable solutions, creating new opportunities in the market. Despite these growth drivers, the 3D printing polymer market in North America faces challenges such as regulatory issues, intellectual property concerns, and competition from other regions. However, the region's strong technological base, supportive regulatory environment, and high adoption rate of 3D printing technologies position it as a key player in the global 3D printing polymer market. Looking ahead, the North American 3D printing polymer market is expected to continue its growth trajectory, driven by ongoing technological advancements, increasing demand from end-use industries, and a focus on sustainability.

Get Complete Analysis Of The Report - Download Free Sample PDF

The analyzed market exhibits a high degree of fragmentation, primarily attributable to the presence of numerous players operating on both a global and regional scale. The competitive landscape is characterized by a diverse array of companies, each contributing to the overall market dynamics. This fragmentation arises from the existence of specialized solution providers, established industry players, and emerging entrants, all vying for market share. The diversity in market participants is underscored by the adoption of various strategies aimed at expanding the company presence. On a global scale, companies within the studied market are strategically positioning themselves through aggressive expansion initiatives. This often involves entering new geographical regions, targeting untapped markets, and establishing a robust global footprint. The pursuit of global expansion is driven by the recognition of diverse market opportunities and the desire to capitalize on emerging trends and demands across different regions. Simultaneously, at the regional level, companies are tailoring their approaches to align with local market dynamics. Regional players are leveraging their understanding of specific market nuances, regulatory environments, and consumer preferences to gain a competitive edge. This regional focus allows companies to cater to the unique needs of local clientele, fostering stronger market penetration. To navigate the complexities of the fragmented market, companies are implementing a range of strategies. These strategies include investments in research and development to stay at the forefront of technological advancements, mergers and acquisitions to consolidate market share, strategic partnerships for synergies, and innovation to differentiate products and services. The adoption of such multifaceted strategies reflects the competitive nature of the market, with participants continually seeking avenues for growth and sustainability. In essence, the high fragmentation in the studied market not only signifies the diversity of players but also underscores the dynamism and competitiveness that drive ongoing strategic maneuvers. As companies explore various avenues for expansion, the market continues to evolve, presenting both challenges and opportunities for industry stakeholders.

Some Prominent players in the global 3D printing plastics market include:

Recent Development:

1) In January 2024, Align Technology, Inc. (Align) (Nasdaq: ALGN), a prominent global medical device company renowned for its Invisalign® clear aligners, iTero™ intraoral scanners, and exocad™ CAD/CAM software, announced the successful acquisition of Cubicure GmbH. Cubicure is a privately-held company known for its pioneering work in direct 3D printing solutions for polymer additive manufacturing. The company focuses on developing, producing, and distributing innovative materials, equipment, and processes for advanced 3D printing applications. This acquisition is expected to significantly enhance the 3D polymer printing market by introducing new technologies, materials, and processes that will drive innovation and expand the capabilities of 3D printing in various industries, particularly in digital orthodontics and restorative dentistry.

2) November 2023 Formnext event, HP Inc. (Booth D41, Hall 12.1) demonstrated a significant commitment to sustainable manufacturing in the additive manufacturing industry. They showcased new innovations, materials, tools, and expanded software capabilities aimed at accelerating the transition from adoption to scale for both polymer and metal 3D printing. HP also emphasized its leading collaborations with partners and customers such as BMW, Decathlon, and INDO-MIM. This development is poised to bolster the 3D polymer printing market by driving innovation, improving sustainability practices, and expanding the reach of 3D printing technology across various industries.

Q1. What is the Growth Rate of the 3D Printing Polymer Market ?

As per Data Library Research the 3D printing polymer market is estimated at USD 2.1 billion in 2024.

Q2. At what CAGR is the market projected to grow within the forecast period?

3D Printing Polymer Market is projected to register a CAGR of 22.7% over the forecast period.

Q3. What are the factors driving the 3D Printing Polymer market?

Key factors that are driving the growth include the Technological Advancements and Increasing Adoption Across Industries.

Q4. Which region has the largest share of the 3D Printing Polymer market? What are the largest region's market size and growth rate?

North America has the largest share of the market. For detailed insights on the largest region's market size and growth rate request a sample here.

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model