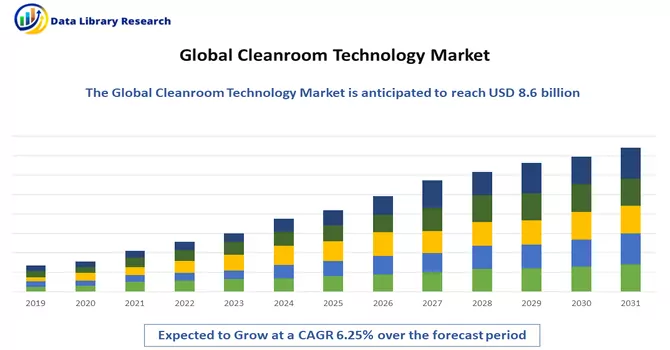

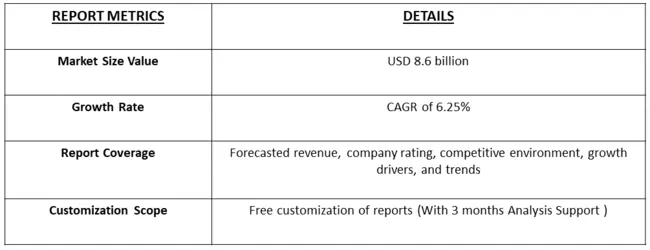

The cleanroom technology market, valued at USD 8.6 billion in 2023, is expected to register a CAGR of 6.25% during the forecast period of 2023 to 2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

Cleanroom technology refers to a specialized environment that is designed and maintained to minimize contamination, particularly in terms of airborne particles, dust, microbes, and chemical vapours. Cleanrooms are essential in industries such as semiconductor manufacturing, pharmaceuticals, biotechnology, aerospace, and other fields where precise control over environmental conditions is crucial for product quality and reliability. Cleanroom technology involves stringent control measures, including high-efficiency air filtration systems, controlled airflow patterns, regulated temperature and humidity levels, and strict procedures for personnel attire and behavior. The goal is to create an environment with minimal levels of particulate and microbial contamination to ensure the integrity of processes, research, or manufacturing activities taking place within the cleanroom. Cleanroom technology plays a vital role in industries where even tiny particles can have a significant impact on the quality and functionality of products, making it an essential component in the pursuit of precision and reliability in various high-tech and sensitive applications.

The cleanroom technology market is propelled by several key growth drivers, with the increasing demand for contaminant-free environments across industries being a primary factor. Sectors such as pharmaceuticals, biotechnology, and semiconductor manufacturing rely on cleanroom facilities to maintain stringent quality standards in their processes. The surge in research and development activities, coupled with the rising focus on precision manufacturing and technological advancements, drives the need for advanced cleanroom solutions. Regulatory requirements emphasizing product quality and safety also contribute to market growth. Additionally, the expanding scope of applications, such as in the healthcare and electronics sectors, further accelerates the adoption of cleanroom technology. As industries continue to prioritize product integrity and reliability, the cleanroom technology market is poised for sustained growth, offering indispensable solutions for contamination control in critical operational environments.

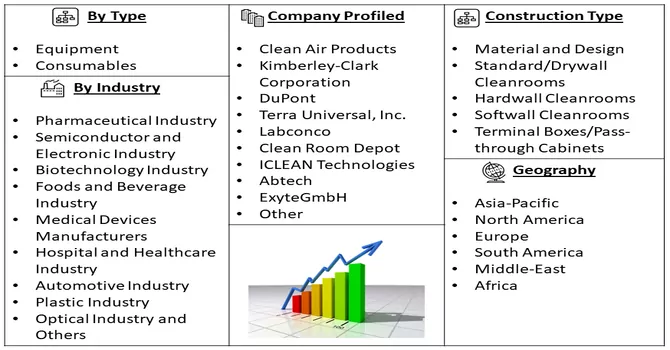

Market Segmentation:

The cleanroom technology market Type (Equipment and Consumables), Construction Type (Material and Design, Standard/Drywall Cleanrooms, Hardwall Cleanrooms, Softwall Cleanrooms, Terminal Boxes/Pass-through Cabinets), Industry (Pharmaceutical Industry, Semiconductor and Electronic Industry, Biotechnology Industry, Foods and Beverage Industry, Medical Devices Manufacturers, Hospital and Healthcare Industry, Automotive Industry, Plastic Industry, Optical Industry and Others) and Geography (North America, Europe, Asia-Pacific, and Rest of the World). The report offers market size and forecasts for the Robotic Lawn Market in value (USD Billion) for all the above segments.

For Detailed Market Segmentation - Download Free Sample PDF

The cleanroom technology market is witnessing notable trends that reflect the evolving landscape of contamination control solutions. Increasing adoption of modular cleanroom systems is a prominent trend, providing flexibility and cost-effectiveness in facility design. Growing demand for nanotechnology and biotechnology applications propels the need for stringent cleanroom standards, fostering innovation in cleanroom technology. Moreover, the pharmaceutical and healthcare sectors are experiencing a surge in cleanroom adoption, driven by a heightened focus on product safety and regulatory compliance. The integration of advanced technologies like IoT and robotics for real-time monitoring and maintenance of cleanroom conditions is also gaining traction, enhancing operational efficiency. Additionally, as sustainability gains prominence, cleanroom technology is evolving to incorporate eco-friendly materials and energy-efficient designs. These trends collectively signify a dynamic market adapting to the diverse needs of industries reliant on cleanroom environments for precision manufacturing and research activities.

Market Drivers:

Technological advancements, such as the integration of IoT for real-time monitoring and robotics for automated maintenance

Technological advancements in the cleanroom technology market are transforming operational efficiency, with notable strides in the integration of Internet of Things (IoT) for real-time monitoring and robotics for automated maintenance. The incorporation of IoT in cleanroom facilities allows for comprehensive monitoring of critical parameters, such as temperature, humidity, and particle levels. Real-time data collection and analysis enable proactive response to deviations, ensuring optimal conditions are maintained. This not only enhances the precision of cleanroom processes but also facilitates predictive maintenance, reducing downtime and minimizing disruptions. Simultaneously, the infusion of robotics in cleanroom maintenance represents a paradigm shift in facility management. Automated robotic systems streamline routine maintenance tasks, such as cleaning and equipment inspections, reducing the need for human intervention and minimizing the risk of contamination. Robotics not only enhance the speed and accuracy of maintenance operations but also contribute to a safer and more controlled cleanroom environment. The synergistic integration of IoT and robotics not only aligns with the broader Industry 4.0 trends but also signifies a strategic leap forward in the evolution of cleanroom technology, offering advanced solutions that redefine the standards of contamination control and operational efficiency in critical environments.

Rising awareness of the importance of contamination control and the pursuit of precision manufacturing

The rising awareness of the importance of contamination control and the pursuit of precision manufacturing is a significant driver shaping the landscape of industries reliant on cleanroom technology. As industries such as pharmaceuticals, biotechnology, electronics, and healthcare recognize the critical impact of contaminants on product quality and safety, there is an increased emphasis on maintaining ultra-clean environments. This awareness is driving investments in advanced cleanroom technologies to ensure stringent control over particle levels, temperature, and humidity. In the pursuit of precision manufacturing, organizations are acknowledging that even minute particles can have substantial implications on the reliability and functionality of products. As a result, cleanroom facilities have become integral to manufacturing processes where precision and quality are paramount. The adoption of cleanroom technology is seen not only as a regulatory necessity but also as a strategic imperative to meet consumer expectations for high-quality, contaminant-free products. The convergence of this heightened awareness and the pursuit of precision manufacturing is reshaping industry standards. It underscores a commitment to delivering products with exceptional quality, reliability, and adherence to regulatory requirements. Cleanroom technology plays a pivotal role in this paradigm, offering controlled environments that enable industries to achieve the utmost precision in their manufacturing processes, ensuring the delivery of products that meet the highest standards of contamination control and reliability.

Market Restraints:

Several market restraints impact the cleanroom technology market, posing challenges to its growth trajectory. One significant restraint is the high initial cost associated with establishing and maintaining cleanroom facilities. The stringent requirements for specialized infrastructure, controlled environments, and sophisticated equipment contribute to substantial upfront expenses, acting as a barrier to entry for smaller enterprises and organizations with budget constraints. Another restraint is the complexity of cleanroom technology implementation and the need for highly skilled personnel to manage and operate these facilities. The intricate nature of cleanroom design and the stringent protocols for contamination control demand specialized expertise, leading to increased operational costs and a potential shortage of skilled professionals. Regulatory compliance poses an additional challenge, especially with evolving standards and stringent guidelines across industries. Keeping up with these regulations and ensuring continuous adherence can be demanding, requiring ongoing investments in technology upgrades and procedural adjustments. The global supply chain disruptions, as witnessed during events like the COVID-19 pandemic, also present a restraint. Delays in equipment procurement, scarcity of specialized components, and interruptions in logistics can impact the timely establishment or expansion of cleanroom facilities, affecting market growth. Furthermore, the reluctance of some industries to adopt cleanroom technology due to perceived overregulation or lack of awareness hinders market expansion. In sectors where contamination control is not historically emphasized, convincing stakeholders of the necessity and benefits of cleanroom technology becomes a challenge. Thus, the high costs, complexity of implementation, regulatory demands, supply chain vulnerabilities, and industry-specific hesitations collectively act as restraints, requiring strategic measures and innovations to address and overcome these challenges in the cleanroom technology market.

The COVID-19 pandemic has had a multifaceted impact on the cleanroom technology market. While the crisis underscored the critical importance of contamination control and cleanroom technologies, it also introduced challenges and disruptions. In response to the heightened awareness of virus transmission, there was an increased demand for cleanroom technology in healthcare facilities, pharmaceutical manufacturing, and biotechnology research. The urgency to ensure sterile environments and prevent cross-contamination became paramount, driving investments in cleanroom infrastructure. However, the pandemic also brought about disruptions to the global supply chain, impacting the production and delivery of cleanroom technology components. Delays in manufacturing, shortages of essential materials, and logistical challenges hindered the timely implementation of cleanroom facilities. The economic uncertainties induced by the pandemic also led to budget constraints for some organizations, affecting their ability to invest in new cleanroom projects. Moreover, the focus on combating COVID-19 diverted attention and resources away from non-pandemic-related cleanroom projects in certain industries. For instance, industries like semiconductor manufacturing and aerospace, which typically rely on cleanroom technology, experienced shifts in priorities and timelines. As the world continues to navigate the pandemic's evolving landscape, the cleanroom technology market is expected to rebound and adapt to the new normal. The lessons learned from COVID-19 underscore the critical role of cleanroom technologies in maintaining controlled environments for research, manufacturing, and healthcare, potentially driving sustained growth and innovations in the post-pandemic era.

Segmental Analysis:

Material and Design Segment is Expected to Witness Significant Growth Over the Forecast Period

Material and design play pivotal roles in shaping the landscape of the cleanroom technology market, influencing the efficiency, effectiveness, and adaptability of these controlled environments. The choice of materials for cleanroom construction is critical in ensuring a contamination-free atmosphere. Smooth, non-porous surfaces, often made of stainless steel or other easy-to-clean materials, are favored to prevent the accumulation of particles and facilitate thorough cleaning. Flooring materials are selected for their ability to resist chemical agents and maintain cleanliness. The design of cleanrooms encompasses architectural elements, HVAC (Heating, Ventilation, and Air Conditioning) systems, and layout configurations. The cleanroom's layout is carefully planned to minimize the risk of cross-contamination, with zones designated for different cleanliness levels. The HVAC system plays a crucial role in controlling air quality, temperature, and humidity. High-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters are integral to the design, capturing airborne particles and ensuring a controlled airflow pattern that minimizes the presence of contaminants. Modularity is a growing trend in cleanroom design, allowing for flexibility and scalability. Modular cleanroom systems offer the advantage of easier expansion or modification, adapting to changing requirements in industries such as pharmaceuticals, biotechnology, and electronics manufacturing. Technological advancements in cleanroom design include the integration of smart sensors for real-time monitoring of environmental parameters. This allows for proactive management and immediate responses to deviations, maintaining the integrity of the controlled environment. The pursuit of sustainability is influencing cleanroom design, with a focus on energy-efficient HVAC systems, eco-friendly materials, and waste reduction strategies. As industries increasingly prioritize environmental responsibility, cleanroom technology is evolving to align with these sustainability goals. Thus, the materials chosen for construction and the design principles applied to cleanrooms are pivotal factors in ensuring their efficacy. The ongoing integration of innovative materials, modular design approaches, and sustainability considerations signifies a dynamic evolution within the cleanroom technology market, as it continues to meet the evolving demands of industries requiring precision and contamination control.

Pharmaceutical Industry Segment is Expected to Witness Significant Growth Over the Forecast Period

The pharmaceutical industry constitutes a cornerstone in the cleanroom technology market, driving demand for contamination-free environments essential in ensuring the production of safe and high-quality medications. Cleanroom technology plays a pivotal role in pharmaceutical manufacturing, where precision and stringent control over environmental conditions are imperative to prevent contamination that could compromise product efficacy and patient safety. As the industry continues to innovate, with the development of advanced therapies and vaccines, the demand for state-of-the-art cleanroom facilities is expected to persist and evolve. The COVID-19 pandemic has further highlighted the critical role of pharmaceutical cleanrooms, particularly in vaccine manufacturing and maintaining rigorous cleanliness standards. Cleanroom technology remains an indispensable asset, supporting the pharmaceutical sector in delivering safe and effective medications while meeting the highest quality standards.

North America Region is Expected to Witness Significant Growth Over the Forecast Period

North America stands as a significant and dynamic hub in the global cleanroom technology market, showcasing robust growth and technological advancements. The region's prominence is driven by the stringent regulatory frameworks governing industries such as pharmaceuticals, biotechnology, healthcare, and electronics, compelling organizations to invest in cutting-edge cleanroom technologies. The pharmaceutical sector, in particular, plays a pivotal role, with the demand for contamination-free environments escalating to ensure the quality and safety of drug manufacturing. The prevalence of advanced research and development activities, coupled with a strong focus on technological innovation, propels the adoption of state-of-the-art cleanroom solutions. The semiconductor and electronics industries also contribute significantly to the demand for cleanroom technology in North America, with a need for precision manufacturing environments to ensure the reliability of electronic components. The COVID-19 pandemic underscored the critical role of cleanroom facilities in pharmaceutical manufacturing and biotechnology research, further driving investments and awareness in the region. Additionally, the ongoing trend of personalized medicine and advancements in biopharmaceuticals aligns with the need for highly controlled environments, boosting the cleanroom technology market. North America's cleanroom technology market is characterized by a competitive landscape, with key players focusing on technological innovation, modularity, and sustainability. The region's commitment to environmental responsibility is reflected in the integration of eco-friendly materials and energy-efficient designs within cleanroom facilities. Thus, North America's cleanroom technology market exhibits a robust and evolving landscape, driven by regulatory compliance, technological advancements, and the region's leadership in key industries. The persistent demand for contamination control, coupled with ongoing advancements, positions North America as a vital player in shaping the future of cleanroom technology.

Get Complete Analysis Of The Report - Download Free Sample PDF

The analyzed market exhibits a high degree of fragmentation, primarily attributable to the presence of numerous players operating on both a global and regional scale. The competitive landscape is characterized by a diverse array of companies, each contributing to the overall market dynamics. This fragmentation arises from the existence of specialized solution providers, established industry players, and emerging entrants, all vying for market share. The diversity in market participants is underscored by the adoption of various strategies aimed at expanding the company presence. On a global scale, companies within the studied market are strategically positioning themselves through aggressive expansion initiatives. This often involves entering new geographical regions, targeting untapped markets, and establishing a robust global footprint. The pursuit of global expansion is driven by the recognition of diverse market opportunities and the desire to capitalize on emerging trends and demands across different regions. Simultaneously, at the regional level, companies are tailoring their approaches to align with local market dynamics. Regional players are leveraging their understanding of specific market nuances, regulatory environments, and consumer preferences to gain a competitive edge. This regional focus allows companies to cater to the unique needs of local clientele, fostering stronger market penetration. To navigate the complexities of the fragmented market, companies are implementing a range of strategies. These strategies include investments in research and development to stay at the forefront of technological advancements, mergers and acquisitions to consolidate market share, strategic partnerships for synergies, and innovation to differentiate products and services. The adoption of such multifaceted strategies reflects the competitive nature of the market, with participants continually seeking avenues for growth and sustainability. In essence, the high fragmentation in the studied market not only signifies the diversity of players but also underscores the dynamism and competitiveness that drive ongoing strategic maneuvers. As companies explore various avenues for expansion, the market continues to evolve, presenting both challenges and opportunities for industry stakeholders.

Some of the key market players working in this segment are:

Recent Development:

1) In May 2021, Labconco unveiled the Purifier Axiom Biosafety Cabinet, marking a significant addition to their product portfolio. This state-of-the-art cabinet is meticulously crafted with a suite of features tailored to meet the requirements of microbiological applications. Labconco's innovative design and commitment to biosafety are evident in the Purifier Axiom, positioning it as a cutting-edge solution for laboratory environments. This announcement underscores Labconco's dedication to providing advanced tools and equipment that cater specifically to the evolving demands and standards within the field of microbiology, offering researchers a reliable and efficient biosafety cabinet for their crucial work.

2) In 2021, a contractual agreement was formalized between Wynnchurch Capital in the United States and Exyte Group in Germany, delineating Exyte's acquisition of the Critical Process Systems Group (CPS). This strategic move signifies a significant expansion of Exyte's capabilities, particularly within the semiconductor, biopharmaceutical, and life sciences sectors. The acquisition is poised to enhance Exyte's overall portfolio, providing an enriched array of solutions for existing and prospective clients operating in these industries. By integrating the specialized expertise of CPS into its offerings, Exyte aims to strengthen its position as a leading provider of critical process solutions, reinforcing its commitment to delivering cutting-edge solutions and services to clients in the dynamic fields of semiconductor manufacturing, biopharmaceuticals, and life sciences.

Q1. What was the Cleanroom Technology Market size in 2023?

As per Data Library Research the cleanroom technology market, valued at USD 8.6 billion in 2023.

Q2. At what CAGR is the Cleanroom Technology market projected to grow within the forecast period?

Cleanroom Technology Market is expected to register a CAGR of 6.25% during the forecast period.

Q3. What segments are covered in the Cleanroom Technology Market Report?

By Type, By Construction Type, By Industry and Geography these segments are covered in the Cleanroom Technology Market Report

Q4. Who are the key players in Cleanroom Technology Market?

Some key players operating in the market include

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model