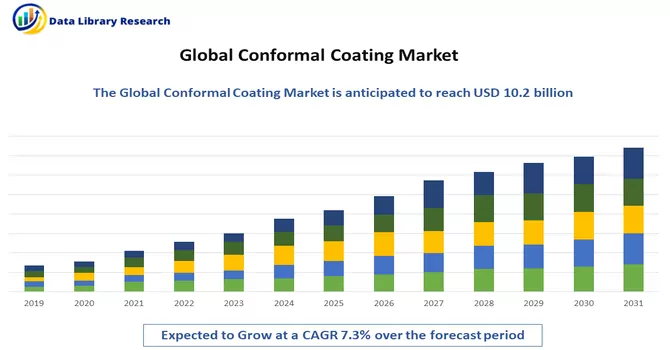

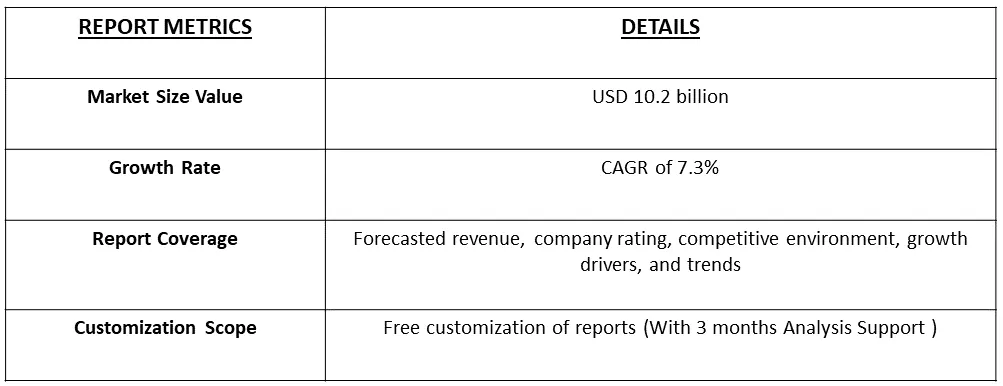

The global conformal coatings market size reached USD 10.2 billion in 2023, and it is expected to register a CAGR of 7.3% during the forecast period from 2024 to 2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

Conformal coatings are thin protective films applied to electronic circuitry to protect it from environmental factors such as moisture, dust, chemicals, and temperature extremes. These coatings "conform" to the contours of the circuit board, providing a barrier that prevents corrosion and insulation against electrical leakage. Conformal coatings are commonly used in industries where electronics are exposed to harsh environments, such as automotive, aerospace, military, and industrial applications. They can be applied using various methods, including spraying, dipping, brushing, or selective coating, and are typically made from materials such as acrylics, silicones, polyurethanes, and epoxies.

The demand for conformal coatings has surged due to the continuous miniaturization of electronics and circuitry in recent years. Choosing the right application method and type of coating has become critical. The consumer electronics sector, in particular, is driving this demand, as there is a growing need to protect PCBs from moisture, dust, heat, and other harsh environmental factors. Additionally, the automotive, electrical and electronics, medical, and semiconductor industries are also significant contributors to the growth of the conformal coating market. The rapid growth of the consumer electronics sector worldwide has led to the widespread adoption of conformal coatings in mobile phones and domestic electronic devices. These coatings are essential for ensuring the long-term reliability and performance of electronic components, especially in devices that are exposed to challenging environmental conditions. Overall, the increasing demand for conformal coatings across various industries underscores the importance of these coatings in protecting electronic components and ensuring the durability and reliability of modern electronic devices.

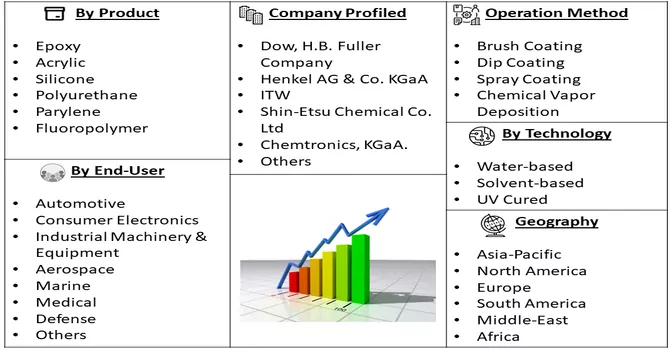

Market Segmentation: The Conformal Coatings Market is Segmented by Product (Epoxy, Acrylic, Silicone, Polyurethane, Parylene, and Fluoropolymer) Operation Method (Brush Coating, Dip Coating, Spray Coating, and Chemical Vapor Deposition) Technology (Water-based, Solvent-based, and UV Cured) End-User (Automotive, Consumer Electronics, Industrial Machinery & Equipment, Aerospace, Marine, Medical, Defense, and Others) and Geography (North America, Europe, Asia-Pacific, Latin America, and Middle East and Africa). The Market Sizes and Forecasts are Provided in Terms of Value (USD) for all the Above Segments.

For Detailed Market Segmentation - Download Free Sample PDF

The conformal coatings market is witnessing several key trends shaping its growth. These include a growing demand for high-performance coatings that offer protection against moisture, dust, and chemicals, along with a focus on environmental sustainability driving the development of eco-friendly coatings. Rapid technological advancements, especially in materials and application methods, are driving innovation, while the automotive electronics sector's increasing complexity is boosting demand. Aerospace and defence sectors also contribute significantly, requiring specialized coatings for electronics in harsh environments. Emerging trends include self-healing coatings for durability and nano-coatings for enhanced protection, highlighting a dynamic and evolving market.

Market Drivers:

Increasing Use of Electronics in Various Industries

The integration of electronics into various industries, including automotive, aerospace, consumer electronics, and healthcare, is driving the demand for conformal coatings. These coatings are essential for protecting electronic components from environmental hazards such as moisture, dust, and chemicals, which can otherwise compromise their performance and lifespan. As industries increasingly depend on electronic systems for critical functions, the importance of conformal coatings in ensuring the reliability and longevity of these components is becoming more pronounced. The steady growth in demand for conformal coatings is a testament to their indispensable role in modern electronics manufacturing and application.

Increasing Demand for High-Performance Coatings

The demand for high-performance conformal coatings is increasing, driven by the need for superior protection against moisture, dust, chemicals, and extreme temperatures. Manufacturers are intensifying their efforts to create coatings that not only meet strict industry standards but also provide durable and reliable protection over an extended period. This focus on developing advanced coatings is essential to ensure the longevity and performance of electronic components, especially in industries where reliability is critical, such as automotive, aerospace, and industrial electronics. Thus, such factors are driving the growth of the studied market over the forecast period.

Market Restraints:

Rising Conformal Coating Failure Mechanisms and Rework

Failures in conformal coatings typically occur due to either the incorrect choice of coating material or the improper design of the coating process. It is crucial to select the appropriate application technique and coating material for the specific requirements of the application. Common issues that can arise during the dispensing and curing of conformal coatings include delamination, cracking, capillary flow, and de-wetting, which can lead to the need for reworking or result in flaws in the coating. For example, acrylic coatings are relatively easy to remove using chemical solvents, while epoxy and parylene coatings are more challenging to remove. Choosing the right coating material and applying it correctly can help prevent these issues and ensure the effectiveness of the conformal coating in protecting electronic components from environmental factors.

The COVID-19 pandemic had a mixed impact on the conformal coating market. Initially, the market faced challenges due to disruptions in supply chains, production shutdowns, and reduced demand from end-use industries such as automotive, aerospace, and electronics. The restrictions on movement and business operations imposed to curb the spread of the virus led to delays in projects and a decline in new orders. However, as the pandemic progressed, the demand for conformal coatings began to recover, driven by several factors. The increased focus on hygiene and cleanliness led to a surge in demand for electronics used in healthcare and medical devices, which require conformal coatings for protection. The shift towards remote working and online services also boosted demand for electronic devices, further driving the need for conformal coatings. Additionally, the pandemic highlighted the importance of resilient and reliable supply chains, leading to increased interest in conformal coatings as a means of protecting electronic components from future disruptions. This has spurred investment in advanced coatings that offer enhanced protection and durability. Thus, while the COVID-19 pandemic initially posed challenges for the conformal coating market, it also created new opportunities for growth. The increased demand for electronic devices and the focus on supply chain resilience are expected to drive the market's recovery and growth in the coming years.

Segmental Analysis:

Fluoropolymer Segment is Expected to Witness Significant Growth Over the Forecast Period

The fluoropolymer and conformal coatings market is experiencing robust growth driven by increasing demand for high-performance coatings in key industries. Fluoropolymer coatings, known for their exceptional chemical resistance and high-temperature stability, are essential in applications requiring superior protection against harsh environments. They are extensively used in the automotive, aerospace, electronics, and construction sectors. Similarly, the conformal coatings market is expanding rapidly, primarily due to the need to protect electronic components from moisture, chemicals, dust, and extreme temperatures. These coatings are vital for ensuring the reliability and longevity of electronic devices, especially with the ongoing trend of miniaturization in electronics and the growth of automotive electronics. Both markets are witnessing a transition towards environmentally friendly coatings, with a focus on compliance with regulations and reducing environmental impact. Technological advancements, such as self-healing coatings and nano-coatings, are also driving market growth by offering enhanced performance and durability. Thus, the fluoropolymer and conformal coatings market presents significant opportunities for growth, driven by the increasing demand for high-performance, durable, and environmentally friendly coatings across diverse industries.

Brush Coating Segment is Expected to Witness Significant Growth Over the Forecast Period

The brush coating segment is a significant component of the conformal coating market, offering a cost-effective and versatile method for applying coatings to electronic components. This technique involves manually applying the coating material with a brush, providing precise control over coverage and thickness. Brush coating is favoured for its simplicity and ease of use, making it suitable for small-scale production or repair work. It allows for uniform protection across components and can be used with a variety of coating materials, including acrylics, silicones, and urethanes. Despite its advantages, brush coating has limitations, such as being time-consuming and labour-intensive, especially for large-scale production. The manual application process can also lead to variations in coating thickness, potentially impacting performance. However, brush coating remains popular for its cost-effectiveness and simplicity, particularly in applications where these factors are crucial. As technology advances, there may be improvements in brush coating techniques to enhance efficiency and consistency, ensuring its continued relevance in the conformal coating market.

Water-based Segment is Expected to Witness Significant Growth Over the Forecast Period

The water-based segment is a significant and rapidly expanding sector within the conformal coating market, driven by the increasing demand for environmentally friendly and sustainable coating solutions. Water-based conformal coatings utilize water as the primary solvent, offering a safer alternative to traditional solvent-based coatings that use volatile organic compounds (VOCs). One of the primary advantages of water-based coatings is their low VOC content, which ensures compliance with stringent environmental regulations and promotes improved air quality. This eco-friendly nature has propelled their adoption across industries such as electronics, automotive, and aerospace. Water-based coatings also boast excellent adhesion and protection properties, ensuring the durability and reliability of electronic components. They can be applied using various methods, including spraying, dipping, and brushing, providing versatility in application. However, challenges such as sensitivity to humidity during application and longer drying times compared to solvent-based coatings exist. Despite these challenges, the water-based segment is expected to continue its growth trajectory, driven by the increasing focus on sustainability and environmental stewardship. Manufacturers are actively investing in research and development to enhance the performance and efficiency of water-based coatings, further bolstering their appeal across industries.

Automotive Segment is Expected to Witness Significant Growth Over the Forecast Period

The automotive segment is a significant driver of growth in the conformal coating market, primarily due to the increasing integration of electronic components in vehicles. Conformal coatings play a crucial role in safeguarding these components from harsh environmental conditions, ensuring their reliability and longevity. In the automotive industry, conformal coatings are utilized in various applications, including engine control units (ECUs), sensors, and electronic control modules. These coatings are essential for protecting electronic systems, especially in vehicles operating in challenging environments. The growing adoption of electric vehicles (EVs) and autonomous driving technologies in the automotive sector is further fueling the demand for conformal coatings. EVs require robust protection for their intricate electronic systems, making conformal coatings indispensable for ensuring optimal performance and durability. Moreover, the trend towards connected cars and smart technologies is creating new opportunities for conformal coatings. These coatings are critical for protecting the sensitive electronics that enable features such as infotainment systems, navigation systems, and advanced driver assistance systems (ADAS). Thus, the automotive segment presents a significant growth opportunity for the conformal coating market, with increasing demand for coatings that offer high performance, durability, and reliability to protect electronic components in modern vehicles.

North America Region is Expected to Witness Significant Growth Over the Forecast Period

North America is a prominent region in the conformal coating market, driven by the presence of a robust electronics industry and stringent regulatory standards. The region is home to several key players in the conformal coating market, contributing to its growth and innovation.i In North America, the demand for conformal coatings is primarily driven by the automotive, aerospace, and consumer electronics industries. These industries require reliable and high-performance coatings to protect their electronic components from moisture, dust, and other environmental factors. The region's focus on technological advancement and innovation is also driving the adoption of advanced conformal coating solutions. Manufacturers in North America are investing in research and development to develop coatings that offer superior protection and performance, further boosting market growth. Furthermore, the stringent environmental regulations in North America are driving the adoption of eco-friendly and low-VOC conformal coatings. These coatings are designed to minimize environmental impact while offering excellent protection for electronic components. Thus, North America is a key region in the conformal coating market, characterized by its strong electronics industry, focus on innovation, and adherence to stringent environmental standards.

Get Complete Analysis Of The Report - Download Free Sample PDF

The analyzed market exhibits a high degree of fragmentation, primarily attributable to the presence of numerous players operating on both a global and regional scale. The competitive landscape is characterized by a diverse array of companies, each contributing to the overall market dynamics. This fragmentation arises from the existence of specialized solution providers, established industry players, and emerging entrants, all vying for market share. The diversity in market participants is underscored by the adoption of various strategies aimed at expanding the company presence. On a global scale, companies within the studied market are strategically positioning themselves through aggressive expansion initiatives. This often involves entering new geographical regions, targeting untapped markets, and establishing a robust global footprint. The pursuit of global expansion is driven by the recognition of diverse market opportunities and the desire to capitalize on emerging trends and demands across different regions. Simultaneously, at the regional level, companies are tailoring their approaches to align with local market dynamics. Regional players are leveraging their understanding of specific market nuances, regulatory environments, and consumer preferences to gain a competitive edge. This regional focus allows companies to cater to the unique needs of local clientele, fostering stronger market penetration. To navigate the complexities of the fragmented market, companies are implementing a range of strategies. These strategies include investments in research and development to stay at the forefront of technological advancements, mergers and acquisitions to consolidate market share, strategic partnerships for synergies, and innovation to differentiate products and services. The adoption of such multifaceted strategies reflects the competitive nature of the market, with participants continually seeking avenues for growth and sustainability. In essence, the high fragmentation in the studied market not only signifies the diversity of players but also underscores the dynamism and competitiveness that drive ongoing strategic manoeuvres. As companies explore various avenues for expansion, the market continues to evolve, presenting both challenges and opportunities for industry stakeholders. Some of the key market players working in this segment are:

Recent Development:

1) In January 2023, Dow launched a new website, dowablatives.com, aimed at connecting customers with its range of DOWSIL protective silicone ablatives and the latest material innovations. This initiative is designed to support the rapidly growing aerospace and satellite industries by providing easy access to proven protective solutions. The website serves as a platform for showcasing Dow's expertise in this field and highlights its commitment to advancing technology and materials for aerospace applications.

2) In October 2020, Henkel AG & Co. KGaA announced an investment in Actnano, an advanced materials startup company headquartered in Massachusetts, U.S. Actnano provided tailored conformal coatings technology for the protection of printed circuit boards in a variety of applications in growing electronics segments. This investment contributed to the advancement of conformal coating technology, offering specialized solutions for electronic component protection in various industries.

Q1. What was the Conformal Coating Market size in 2023?

As per Data Library Research the global conformal coatings market size reached USD 10.2 billion in 2023.

Q2. What is the Growth Rate of the Conformal Coating Market ?

Conformal Coating Market is expected to register a CAGR of 7.3% during the forecast period.

Q3. Who are the key players Conformal Coating Market?

Some key players operating in the market include

Q4. What are the factors driving the Conformal Coating Market?

Key factors that are driving the growth include the Increasing Use of Electronics in Various Industries and Increasing Demand for High-Performance Coatings.

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model