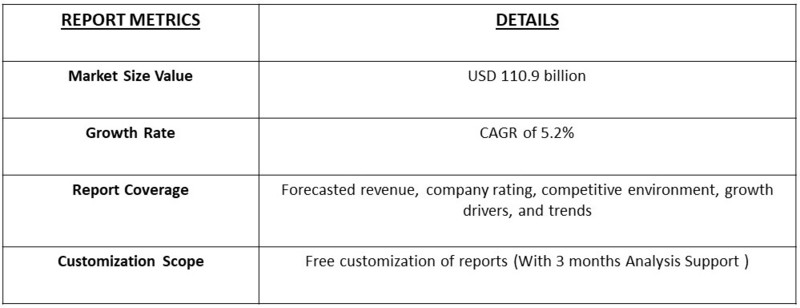

The Mining Equipment Repair and Rebuild Market is currently valued at USD 110.9 billion in 2022 and is expected to register a CAGR of 5.2% over the forecast period, 2022-2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

Mining equipment can prevent workplace accidents and fatalities due to faulty equipment. Also, by keeping machinery in good condition, companies can reduce wear and tear, lower maintenance costs, and prolong the lifespan of their equipment.

Rapid industrialization and globalization for improving a well-functioning economy are further driving the mining equipment market. Furthermore, the deployment of innovative services and parts such as part replacement services, maintenance services, fleet services, and so on further raises the market’s growth. The third-party service providers also offer predictive maintenance contracts that enable the loss of production, reducing downtime, and also leading to reduce the cost of the research and development of equipment maintenance services and inventors.

With staffing and parts shortages persisting, the market has added facilities, equipment, and personnel to handle the demand. They serve miners short on maintenance personnel, low on parts inventory, and located far from urban centers, and thus the market is expected to witness significant growth over the forecast period.

Segmentation :

The Mining Equipment Repair and Rebuild Market is Segmented

By Equipment :

Services :

Geography :

The report offers the value (in USD million) for the above segments.

For Detailed Market Segmentation - Get a Free Sample PDF

Market Driver

Growing Outsourcing Equipment

Organizations working in the segment of mining equipment repair are turning towards the use of outsourcing equipment to reduce expenses and maintain productivity. Companies are widely making decisions to adopt outsourcing equipment for increasing efficiency. The outsourcing of equipment also results in removing outside vendors, leading to reducing issues while managing the in-house maintenance team. Thus, the growth of outsourcing equipment for businesses to cut down costs and increase production levels will surge the demand for the Mining Equipment Services Market.

Also, an article published by the journal Industrial and Corporate Change in June 2023, reported that innovation in the mining sector is increasing due to sector-specific challenges. The new, innovations are tackling the operational challenges within the sector, such as decreasing ore grades improving blasting strategies, and ensuring the health and safety of employees. This emerging dynamic demonstrates the potential for employment generation and broader economic impacts, opposing the view that the mining sector is an enclave. Thus, such instances are contributing to the growth of the studied market.

Rising Shift to Third-Party Service Vendors Driven by Lower Costs

The necessity of effective machinery maintenance and heavy repair equipment services in the mining industry from third-party vendors is contributing to the studied market’s growth as equipment repair and maintenance services are highly cost-effective which may lead companies to shift towards third-party for offering low-cost services that are reliable and leads to productivity by extending the lifetime of the equipment. Furthermore, the adoption of maintenance services such as predictive and preventive maintenance services will lead to maximizing the system’s uptime, optimization of asset management, and warranty of the equipment life which will further enhance the market’s growth.

Market Restraints

Environmental Effect on The Mining Industry

The negative environmental impacts of mining include climate change, deforestation/habitat destruction, pollution, soil erosion, human-wildlife conflict, and the loss of biodiversity. Thus, due to these reasons, the growth of the market may slow down over the forecast period.

The COVID-19 pandemic significantly impacted the growth of various markets across the globe and so the mining equipment repair and rebuild market impacted the growth of the global market. For instance, an article published by the journal Sustainable Cities and Societies, in October 2021, reported a study conducted revealed that a large group of mining agreements collapsed during the COVID-19 due to the disruption caused by the lockdown, which restricted people as a result of many mining related projects were canceled or delayed. As per the data published by the National Center for Biotechnology Information in July 2022, the number of mining projects decreased by 46.9% globally, thus the market faced significant challenges. In the current scenario, with a resumption of various services, the mining projects have come back to normal, similar to pre-pandemic times, and the market is expected to witness significant traction over the forecast period.

Segmental Analysis Underground Mining Equipment Segment is Expected to witness significant growth Over the Forecast Period

Mining trucks and loaders for underground operations have specially built engines that do not produce emissions but still have enough power to move tons of rock. These machines, ' uses include: Digging. Loading rock or mined material into trucks. Underground mining is used to extract ore from below the surface of the earth safely, economically, and with as little waste as possible. Thus, the segment is expected to witness significant growth over the forecast period.

Maintenance Services Segment is Expected to Witness Significant growth Over the Forecast Period

Well-maintained mining equipment can prevent workplace accidents and fatalities due to faulty equipment. Also, by keeping machinery in good condition, companies can reduce wear and tear, lower maintenance costs, and prolong the lifespan of their equipment. Thus, due to the benefits associated with these equipment, the segment is expected to witness significant growth over the forecast period.

North America is Expected to Witness Significant growth Over the Forecast Period

With the rising consumption of base metals and precious metals in several applications, the mining activities of these metals increased, especially in North American countries such as Canada and Mexico. In addition, the growing adoption of such equipment has led to selective mining operations by exploring high-quality materials and creating embankments and stable surfaces. These factors may provide lucrative opportunities for manufacturers, leading them to expand their product portfolios. For instance, In January 2021, Caterpillar launched three large, next-generation excavators and two ultra-high-definition (UHD) demolition machines. These kinds of development activities are expected to drive the market’s growth in the region.

To Learn More About This Report - Request a Free Sample Copy

The Mining Equipment Repair and Rebuild Market is highly fragmented due to the presence of many market players working globally and regionally. Some of the key market players working in this domain are:-

Key Players :

Recent Development

1) In March 2023: Liugong India, reported its entry into the mining and electric wheel loader segments at Bauma Conexpo India 2023, held in Greater Noida. The new range of equipment launched by Liugong India consists of large excavators, dump trucks, hydrostatic wheel loaders, motor graders, and dozers, designed to work in arduous and tough Indian operating conditions in the most demanding of applications. I

2) June 2022: ARX Construction and Mining Equipment chose EXCON 2022 to launch motor graders – G3200 and G1000, and Blast Hole Drill Rig D3300 besides other machinery. The large grader with its sheer size has attracted the most attention. Such machines are typically used in the Middle East and big mining markets for haul road maintenance. This piece of machine improves the suspension life and tire life on large dumpers. This size of the grader is run with a 240-ton dumper which is typically used in big mining projects.

Q1. How big is the Mining Equipments Repair Market?

The Mining Equipment Repair Market is currently valued at USD 110.9 billion in 2022 and is expected to register a CAGR of 5.2% over the forecast period, 2022-2031.

Q2. Which Region is expected to hold the highest Market share?

North America hold the highest market share

Q3. Which factor is Limiting the growth of Mining Equipments Repair Market?

The negative environmental impacts of mining include climate change, deforestation/habitat destruction, pollution, soil erosion, human-wildlife conflict, and the loss of biodiversity. This can slow down the growth during the forecast period.

Q4. What segments are covered in the Mining Equipments Repair Market Report?

Mining Equipments Repair Market Report Covers segments such as- By Equipment, Services and Geography.

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model