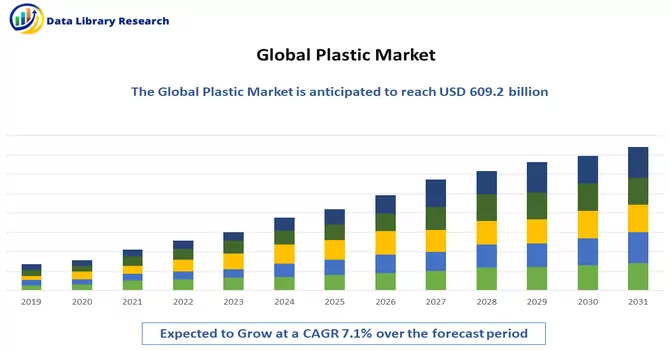

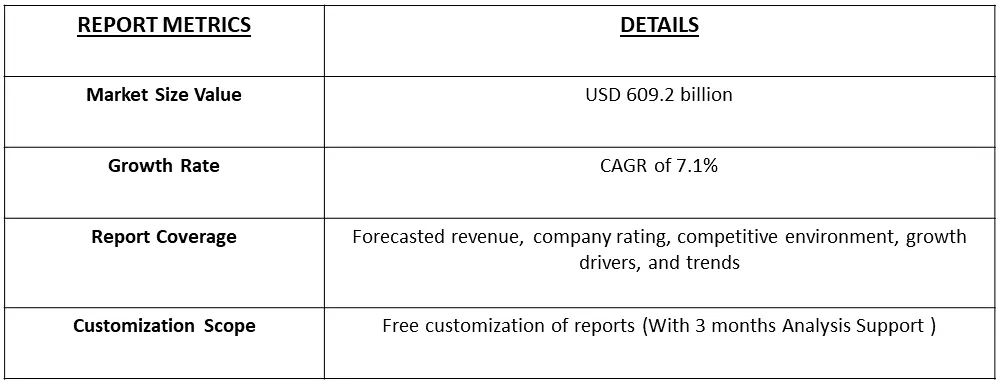

The global plastic market size was estimated at USD 609.2 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.1% from 2024 to 2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

Plastic is a synthetic material made from polymers, which are large molecules composed of repeated subunits called monomers. This versatile material can be moulded into various forms, making it widely used in manufacturing for packaging, construction, electronics, automotive components, medical devices, and consumer goods. While plastics offer durability and versatility, concerns about their environmental impact, including pollution and persistence in the environment, have prompted efforts to develop sustainable alternatives and improve recycling processes.

The growth of the plastic market is driven by several factors. One significant factor is the widespread use of plastics across diverse industries, including packaging, construction, automotive, electronics, and consumer goods. Plastics offer versatility, durability, and cost-effectiveness, making them preferred materials in various applications. Additionally, the continuous innovation in plastic manufacturing technologies, leading to the development of advanced and high-performance plastics, contributes to market expansion. The increasing demand for lightweight materials in industries such as automotive, coupled with the rising need for efficient and sustainable packaging solutions, further fuels the growth of the plastic market. Moreover, the ease of processing and molding plastics into complex shapes enhances their appeal for manufacturers seeking design flexibility. Despite environmental concerns associated with plastic waste, the market continues to grow as efforts are made to address these issues through recycling initiatives and the development of bio-based and biodegradable plastics. Overall, the multifaceted advantages and adaptability of plastics across industries remain key drivers for the sustained growth of the plastic market.

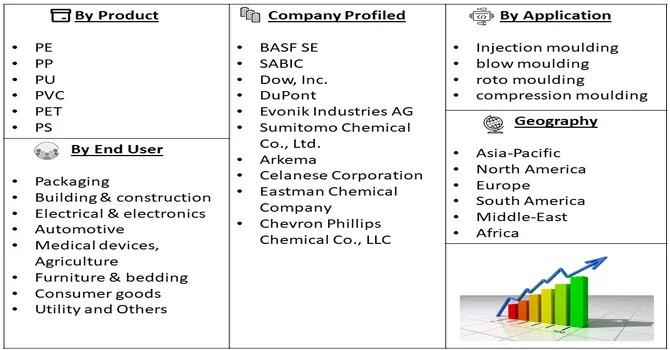

Market Segmentation: The Plastic Market is Segmented by Product (PE, PP, PU, PVC, PET, and PS), Application (Injection moulding, blow moulding, roto moulding, and compression moulding), and End User (Packaging, Building & construction, Electrical & electronics, Automotive, Medical devices, Agriculture, Furniture & bedding, Consumer goods, Utility and Others) and geography (Europe, North America, Latin America, Asia-Pacific, and the Middle East and Africa). The market sizes and forecasts are provided in terms of value (USD) for all the above segments.

For Detailed Market Segmentation - Download Free Sample PDF

Several notable trends shape the plastic market's landscape. One prominent trend is the increasing focus on sustainability and environmental consciousness, driving a growing demand for eco-friendly alternatives to traditional plastics. This has led to the development and adoption of biodegradable and bio-based plastics, as well as an emphasis on improving recycling processes. Another significant trend involves advancements in polymer technology, resulting in the creation of high-performance plastics with enhanced properties, such as improved strength, heat resistance, and durability. Additionally, the rise of the circular economy concept has prompted manufacturers to explore closed-loop recycling systems and design products with end-of-life considerations. The plastic market also witnesses a surge in demand for lightweight materials, especially in the automotive and aerospace sectors, as industries seek to enhance fuel efficiency and reduce emissions. Furthermore, innovations in packaging design, including the development of smart and sustainable packaging solutions, contribute to the evolving dynamics of the plastic market. As regulatory frameworks become more stringent, there is a growing emphasis on reducing single-use plastics, leading to changes in consumer behaviour and a shift towards more sustainable packaging options. Overall, these trends reflect the industry's response to environmental challenges, technological advancements, and changing consumer preferences.

Market Drivers:

Versatility and Application Diversity

Continuous progress in polymer technology has led to the creation of high-performance plastics that boast enhanced properties, marking a significant stride in material innovation. These advancements encompass notable improvements in crucial aspects such as strength, durability, and resistance to external factors like heat and chemicals. The evolution of high-performance plastics has substantially broadened the spectrum of applications for this class of materials. The enhanced strength of these plastics means they can withstand higher levels of stress and load, making them suitable for applications demanding structural integrity and robustness. Improved durability ensures a longer lifespan for products, contributing to sustainability and cost-effectiveness. Additionally, the heightened resistance to factors like heat and chemicals expands the potential applications of these plastics across industries such as automotive, aerospace, electronics, and manufacturing. This innovation is particularly valuable in addressing the diverse and stringent requirements of modern industrial processes, where materials with superior performance characteristics are essential. As a result, high-performance plastics have become integral to the development of cutting-edge products and technologies, shaping the landscape of industries that rely on advanced materials for their continued evolution.

Innovation in Polymer Technology

Plastics distinguish themselves through their remarkable versatility and broad applicability across a diverse array of industries, spanning packaging, construction, automotive, electronics, and healthcare. What sets plastics apart is their innate ability to be moulded into a multitude of forms and sizes, establishing them as the material of choice in a wide range of manufacturing processes. This inherent adaptability of plastics is a key factor in addressing the distinctive needs of each industry, underscoring their pivotal role in contemporary manufacturing practices. In the realm of packaging, plastics offer solutions that can be customized to various shapes and sizes, providing flexibility in design and functionality. In construction, the malleability of plastics allows for the creation of durable and lightweight materials, contributing to both structural integrity and energy efficiency. In the automotive sector, the versatility of plastics is harnessed for manufacturing components that are not only lightweight but also resistant to wear and tear. The electronics industry benefits from the insulating properties of plastics, which help protect and insulate electronic components. Moreover, in healthcare, the ability of plastics to be sterilized and moulded into intricate shapes is instrumental in the production of medical devices and packaging. This adaptability of plastics goes beyond mere convenience; it aligns with the evolving needs of industries, fostering innovation and efficiency. Plastics have become an indispensable cornerstone in modern manufacturing, facilitating advancements and breakthroughs across diverse sectors, and showcasing their enduring significance in shaping the contemporary industrial landscape.

Market Restraints:

Environmental Concerns and Plastic Waste

One significant restraint facing the global plastic market is the environmental impact associated with plastic waste. The persistence of plastics in the environment, coupled with issues like ocean pollution and harm to wildlife, has raised considerable environmental concerns. Regulatory pressures and heightened awareness among consumers regarding the ecological footprint of plastics have led to increased scrutiny and calls for sustainable practices within the industry. Efforts to address these concerns include the development of biodegradable plastics, increased recycling initiatives, and a shift towards circular economy models. However, these measures are still evolving, and addressing the environmental impact of plastic waste remains a critical challenge for the industry.

The COVID-19 pandemic has had a multifaceted impact on the plastic market. While certain segments, particularly those associated with healthcare and packaging, experienced heightened demand for single-use plastics such as personal protective equipment (PPE) and packaging materials for medical supplies, other sectors faced challenges. Lockdowns, disruptions in supply chains, and a slowdown in manufacturing activities contributed to decreased demand in industries like automotive and construction, impacting the consumption of plastic products in these sectors. Additionally, the pandemic heightened awareness about the environmental implications of single-use plastics, leading to increased scrutiny and calls for sustainable alternatives. The plastic industry has responded by emphasizing recycling initiatives, exploring bio-based plastics, and adapting to changing consumer preferences. The pandemic underscored the need for a balanced approach, ensuring the continued utility of plastics in critical applications while addressing environmental concerns and fostering sustainable practices within the industry.

Segmental Analysis:

PE Segment is Expected to Witness Significant Growth over the Forecast Period.

Polyethylene, a versatile and widely used thermoplastic, finds extensive applications across diverse industries due to its exceptional properties. In packaging, polyethene is prevalent in the form of plastic bags, films, and containers, offering durability and flexibility. In the construction sector, it is utilized for pipes, insulation, and geomembranes owing to its resistance to moisture and chemicals. Polyethene's lightweight and robust nature makes it a preferred material in the manufacturing of various consumer goods such as bottles, toys, and household items. In the medical field, it is employed for disposable gloves, syringes, and medical packaging due to its non-reactive and sterile characteristics. Its use extends to agriculture for plastic mulching and irrigation pipes. Additionally, polyethene's insulation properties make it indispensable in the electrical industry for cable insulation. With diverse grades catering to specific needs, polyethene stands out as a crucial material underpinning various aspects of modern life.

Injection Molding Segment is Expected to Witness Significant Growth over the Forecast Period.

Injection moulding is a highly versatile and widely employed manufacturing process in the realm of plastics. It involves injecting molten plastic material into a mould cavity, where it cools and solidifies, taking the shape of the mould. This process is crucial for producing a vast array of plastic products, ranging from intricate and small components to larger and more complex items. The method is favoured for its efficiency, precision, and ability to facilitate mass production at a relatively low cost per unit. Injection moulding plays a pivotal role in diverse industries, including automotive, electronics, consumer goods, and medical devices, due to its capability to create detailed and customized parts with high repeatability. The adaptability of plastics in injection moulding allows for the production of components with varying material properties, meeting specific requirements across applications. The seamless integration of injection moulding and plastics underscores their symbiotic relationship, driving innovation and shaping the landscape of modern manufacturing.

Healthcare Segment is Expected to Witness Significant Growth over the Forecast Period.

Plastics play a pivotal role in the healthcare sector, contributing to advancements in medical technology, safety, and patient care. In medical devices, materials like polyethene, polypropylene, and PVC are extensively used due to their biocompatibility, durability, and ease of sterilization. Intricate components such as syringes, tubing, and surgical instruments are often manufactured using plastic injection moulding techniques. Moreover, plastic packaging ensures the integrity and sterility of medical supplies and pharmaceuticals. Single-use plastics in healthcare, including disposable gloves, gowns, and syringes, have become indispensable for infection control. The lightweight nature of plastics in medical equipment enhances portability and facilitates patient care. Despite these benefits, the environmental impact of single-use plastics in healthcare has prompted a growing emphasis on sustainable alternatives. As technology and materials continue to evolve, the intersection of healthcare and plastics remains dynamic, balancing innovation with the need for environmentally conscious practices in the medical field.

North America Region is Expected to Witness Significant Growth over the Forecast Period.

North America plays a significant role in the global plastic industry, both as a major consumer and producer of plastic products. The region's robust manufacturing infrastructure, coupled with a highly developed consumer market, contributes to the extensive use of plastics in various sectors. In packaging, plastics are widely employed for food and beverage containers, ensuring product safety and prolonging shelf life. The automotive industry in North America utilizes plastics for lightweight components, enhancing fuel efficiency and reducing overall vehicle weight. Moreover, the construction sector incorporates plastics in insulation materials and piping systems. Despite the economic and technological benefits of plastics, North America, like the rest of the world, faces challenges related to plastic waste and environmental concerns. Efforts are underway to address these issues through increased recycling initiatives, the development of sustainable alternatives, and the implementation of stricter regulations. The dynamic interplay between North America and the plastic industry underscores the importance of balancing innovation and environmental responsibility in the region's ongoing relationship with plastics.

Get Complete Analysis Of The Report - Download Free Sample PDF

The preeminent entities in the plastic market exert substantial influence, collectively commanding the largest market share and setting the pace for industry trends. An in-depth examination of the financials, strategy maps, and product portfolios of these key players is undertaken to meticulously delineate the contours of the supply network. By scrutinizing the strategies and financial performances of these leading plastic companies, a comprehensive understanding of their market positioning and dynamics is achieved. This analysis not only sheds light on the competitive landscape but also provides valuable insights into the interconnected relationships and dependencies within the broader supply network of the plastic industry. Some of the market players working in this segment are:

Recent Development:

1) In December of 2023, Biesterfeld AG and Celanese Corporation revealed their collaborative efforts to extend their distribution partnership, aiming to enhance their market presence for plastics in various regions, including Europe, the Middle East & Africa, Southeast Asia, and Brazil.

2) In June 2023, MKS Plastics disclosed a substantial investment of USD 14 million in the expansion of its manufacturing facility located in Tangipahoa Parish. This strategic move is anticipated to result in the doubling of the company's production capacity, enabling them to better serve clients in the petroleum and chemical industry.

Q1. What was the Plastic Market size in 2023?

The global plastic market size was estimated at USD 609.2 billion in 2023.

Q2. At what CAGR is the Plastic market projected to grow within the forecast period?

Plastic market is expected to grow at a compound annual growth rate (CAGR) of 7.1% over the forecast period.

Q3. What segments are covered in the Plastic Market Report?

By Product, By Application, End-User and Geography these segments are covered in the Plastic Market Report.

Q4. What are the factors driving the Plastic market?

Key factors that are driving the growth include the Versatility and Application Diversity and Innovation in Polymer Technology.

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model