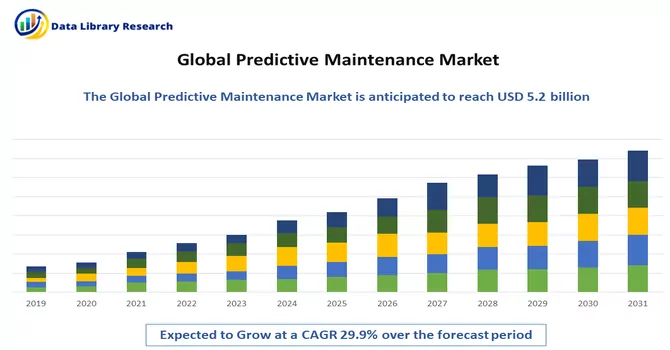

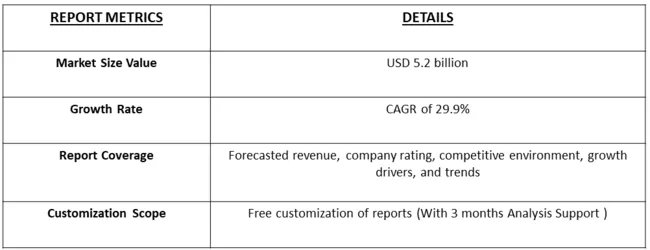

The global predictive maintenance market was valued at USD 5.2 billion in 2022 and is expected to grow at a CAGR of 29.9% during the forecast period, 2023-2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

Predictive maintenance helps organizations optimize their maintenance schedules, reduce overall maintenance costs, extend equipment lifespan, and enhance operational efficiency. This approach is a departure from traditional reactive maintenance, where maintenance is performed only after an equipment failure, leading to increased downtime and potentially higher repair costs.

The predictive maintenance market is driven by several key factors that contribute to its growth and adoption. The increasing integration of advanced technologies, such as the Internet of Things (IoT) and machine learning, plays a pivotal role in enhancing the capabilities of predictive maintenance solutions. The growing awareness among industries about the benefits of proactive maintenance, including reduced downtime, optimized operational efficiency, and cost savings, is fueling the demand for predictive maintenance solutions. Additionally, the rise of big data analytics enables organizations to process and analyze large volumes of data generated by equipment sensors, facilitating more accurate predictions of equipment health and performance. The shift from traditional, reactive maintenance approaches to a predictive and condition-based strategy is further propelled by the desire to prevent unplanned breakdowns and extend the lifespan of critical assets. Moreover, industries such as manufacturing, energy, and transportation are recognizing the strategic value of predictive maintenance in improving overall equipment effectiveness and minimizing disruptions, driving the market's continuous expansion.

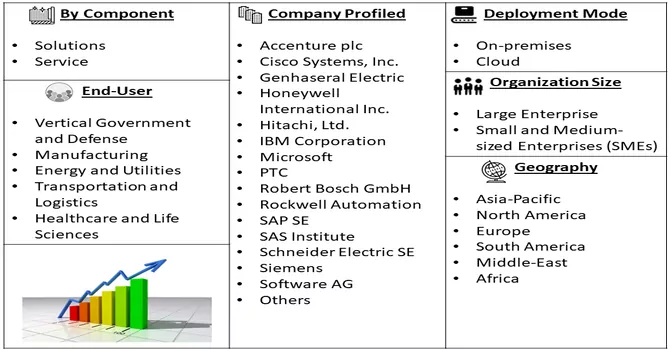

Market Segmentation: Predictive Maintenance Market By Component (Solutions and Service) Deployment Mode (On-premises and Cloud) Organization Size (Large Enterprises, Small and Medium-sized Enterprises (SMEs)) Vertical Government and Defense, Manufacturing, Energy and Utilities, Transportation and Logistics, Healthcare and Life Sciences) and Geography (North America, Europe, Asia-Pacific, Middle East and Africa, and South America). The market size and forecasts are provided in terms of value (in USD million) for the above segments.

For Detailed Market Segmentation - Download Free Sample PDF

The predictive maintenance market is currently characterized by dynamic trends shaping the landscape of maintenance strategies. A prominent shift involves the widespread adoption of advanced technologies, including artificial intelligence and machine learning, to enhance the precision and real-time analysis of equipment data, allowing for early issue detection. The integration of the Industrial Internet of Things (IIoT) is also on the rise, fostering seamless connectivity for data-rich predictive maintenance insights. Cloud-based solutions are gaining traction due to their scalability and accessibility, aligning with the broader trend of digital transformation. Concurrently, the development of predictive analytics models is not only predicting equipment failures but also offering actionable insights for preventive measures, optimizing overall maintenance strategies. Collaborations and partnerships have become integral as industry players recognize the value of interdisciplinary expertise, fostering innovation. Sustainability is emerging as a key focus, with predictive maintenance technologies being leveraged to enhance energy efficiency, reduce waste, and contribute to environmental conservation. This convergence of cutting-edge technologies, a shift towards cloud-based solutions, collaborative partnerships, and sustainability underscores a comprehensive and future-oriented approach to predictive maintenance practices in the industrial sector.

Market Drivers:

Increasing integration of cutting-edge technologies such as artificial intelligence (AI), machine learning (ML), and the Industrial Internet of Things (IIoT).

One significant driver is the increasing integration of cutting-edge technologies such as artificial intelligence (AI), machine learning (ML), and the Industrial Internet of Things (IIoT). These technologies play a crucial role in enabling more accurate and real-time analysis of equipment data, thereby enhancing the predictive capabilities of maintenance solutions. The growing awareness among industries about the benefits of proactive maintenance, including reduced downtime, optimized operational efficiency, and cost savings, is a major catalyst for the escalating demand for predictive maintenance solutions. An illustrative example of the market's momentum is the collaboration between Cisco Systems, Inc. and NTT, a telecom infrastructure services company, in May 2023. This partnership aims to develop and offer real-time data insights, improved decision-making, and enhanced security through the implementation of predictive maintenance, supply chain management, and asset-tracking capabilities. Similarly, in May 2021, TIBCO Software introduced TIBCO Data Virtualization and TIBCO EBX. These software solutions hold significance as they provide users with substantial data potential. This launch further emphasizes the industry's commitment to leveraging innovative tools to unlock and harness the full power of data for predictive maintenance and other applications. Overall, these developments underscore the continuous evolution and expansion of the predictive maintenance market, fueled by technological advancements and strategic collaborations within the industry.

Increasing the implementation of predictive maintenance involves the use of alerts and notifications

The growing adoption of predictive maintenance strategies involves a crucial element: the utilization of alerts and notifications. This proactive approach relies on sophisticated monitoring systems that consistently gather and analyze data from equipment sensors. Upon detecting potential issues or anomalies, these systems promptly generate real-time alerts and notifications. This empowers maintenance teams to receive timely insights into equipment conditions, enabling them to take preventive measures before a failure occurs. The integration of alerts and notifications plays a pivotal role in transitioning maintenance practices from reactive to proactive, effectively reducing unplanned downtime and optimizing overall equipment performance. Through the utilization of this real-time communication, organizations can enhance their responsiveness, prioritize critical maintenance tasks, and ultimately extend the lifespan of their assets. The incorporation of alerts and notifications in predictive maintenance not only mitigates the risk of equipment failures but also contributes to improved operational efficiency and cost savings, establishing it as a fundamental element in the successful deployment of predictive maintenance strategies across diverse industries. An illustrative example of technological advancements supporting this trend is the launch of the SAS Viya platform by SAS Institute in May 2021. This solution significantly enhances information and analysis efficiency by integrating data management solutions into the SAS Viya platform, providing users with a valuable tool for their operations.

Market Restraints:

High Cost of Implementation:

A significant impediment to the widespread adoption of predictive analysis in the business landscape is the substantial initial investment required for deploying advanced analytics and predictive modeling solutions. This financial commitment encompasses acquiring specialized software, recruiting skilled personnel proficient in complex algorithms, and making necessary infrastructure enhancements. For smaller businesses operating within constrained budgets, these expenses serve as a formidable barrier, limiting their ability to leverage the advantages of predictive analysis. The need for a comprehensive technological infrastructure, coupled with the expertise to effectively implement and interpret predictive models, creates a hurdle that smaller organizations may find challenging to overcome. Addressing these cost-related challenges is imperative for fostering a more inclusive adoption of predictive analysis across diverse business sectors. Thus, these factors are expected to slow the growth of the studied market over the forecast period.

The COVID-19 pandemic has significantly impacted the predictive maintenance market, initially posing challenges due to global economic slowdowns, supply chain disruptions, and lockdown measures affecting industries' investment priorities. However, as the pandemic unfolded, it highlighted the crucial role of resilient maintenance strategies, prompting industries, especially in essential sectors, to recognize the value of predictive maintenance in ensuring continuous operations and optimizing resource utilization. The need for remote monitoring solutions became evident as travel restrictions limited on-site personnel. This accelerated the adoption of advanced technologies like artificial intelligence, machine learning, and the Industrial Internet of Things (IIoT) to enhance predictive maintenance capabilities. While initial economic challenges affected spending, the long-term outlook indicates a rebound and increased investment as businesses recover and adapt to the new normal. The pandemic acted as a catalyst for digital transformation and reinforced the strategic importance of predictive maintenance in ensuring business resilience and operational continuity in the face of unforeseen disruptions.

Segmental Analysis:

The Solutions Segment is Expected to Witness Significant Growth Over the Forecast Period

Predictive maintenance solutions represent a proactive approach to equipment and asset management, leveraging advanced technologies to predict and prevent potential failures before they occur. These solutions integrate a range of tools and techniques, including data analytics, artificial intelligence, machine learning, and the Industrial Internet of Things (IIoT). By continuously monitoring and analyzing data from sensors and equipment, predictive maintenance solutions can identify patterns, anomalies, or trends that may indicate impending issues. The key objective is to move away from traditional, reactive maintenance models towards a more strategic and data-driven approach. Predictive maintenance solutions enable organizations to schedule maintenance activities more efficiently, reduce unplanned downtime, extend the lifespan of assets, and optimize overall operational efficiency.

These solutions often include real-time monitoring, predictive analytics models, and automated alert systems to notify maintenance teams of potential issues, allowing for timely interventions. Industries such as manufacturing, energy, transportation, and healthcare are increasingly adopting predictive maintenance solutions to enhance equipment reliability, reduce maintenance costs, and improve overall business productivity. As technology continues to advance, predictive maintenance solutions are evolving, offering more sophisticated insights and contributing to the ongoing digital transformation of various sectors. Thus, these factors are expected to drive the studied segment growth over the forecast period.

Cloud Segment is Expected to Witness Significant Growth Over the Forecast Period

The convergence of cloud computing and predictive maintenance has ushered in a transformative era in the industrial landscape. Cloud-based predictive maintenance solutions leverage the scalability, flexibility, and accessibility inherent in cloud platforms to revolutionize maintenance strategies. Through real-time data processing in the cloud, organizations can deploy more accurate predictive analytics, enabling early identification of potential equipment failures and facilitating proactive maintenance interventions. The cloud's role extends beyond data processing; it fosters remote monitoring, empowering maintenance teams to make informed decisions from anywhere, thereby enhancing operational agility. Cloud-based solutions also facilitate seamless integration with other tools and services, such as artificial intelligence and machine learning, augmenting the sophistication of predictive maintenance analysis. As a cost-effective alternative, cloud-based predictive maintenance eliminates the need for extensive on-premises infrastructure and adopts a pay-as-you-go model. This burgeoning market is witnessing substantial growth as industries recognize the strategic advantages, with companies migrating from traditional on-premises systems to embrace cloud platforms for real-time insights, scalability, and collaborative benefits. The ongoing digital transformation further propels the integration of cloud technologies into predictive maintenance strategies, shaping the future of maintenance practices by driving operational efficiency, reducing downtime, and contributing to overall business resilience.

Small and Medium-sized Enterprises (SMEs) Segment is Expected to Witness Significant Growth Over the Forecast Period

The integration of predictive maintenance solutions in the context of Small and Medium-sized Enterprises (SMEs) represents a significant avenue for technological advancement and operational efficiency. While traditionally associated with larger enterprises, predictive maintenance technologies are becoming increasingly accessible and tailored to the specific needs and resources of SMEs. These solutions offer SMEs the opportunity to shift from reactive to proactive maintenance strategies, thereby reducing downtime, extending the lifespan of critical assets, and optimizing overall operational performance. Cloud-based predictive maintenance, in particular, allows SMEs to leverage scalable and cost-effective solutions, eliminating the need for substantial upfront investments in infrastructure. The adoption of predictive maintenance in SMEs is often driven by the imperative to maximize resource utilization, minimize maintenance costs, and enhance competitiveness. As technology providers recognize the unique requirements of SMEs, there is a growing trend towards offering user-friendly and scalable predictive maintenance solutions that cater to the distinct operational environments and budgets of smaller businesses. The market for predictive maintenance in SMEs is poised for expansion as awareness grows regarding the transformative benefits of these technologies in improving reliability, reducing unplanned downtime, and ultimately contributing to the sustained growth of smaller enterprises.

Healthcare and Lifescience Segment is Expected to Witness Significant Growth Over the Forecast Period

The integration of predictive maintenance solutions within the Healthcare and Life Sciences industry is proving to be a transformative force, enhancing operational efficiency and elevating patient care. In healthcare settings, where precision and reliability are paramount, these solutions utilize advanced technologies such as sensors, data analytics, and machine learning to monitor the real-time condition of medical equipment and facilities. This proactive approach allows healthcare facilities to schedule maintenance activities strategically, minimizing disruptions and optimizing the availability of critical equipment. Similarly, in the Life Sciences sector, predictive maintenance plays a crucial role in preventing equipment failures that could compromise research outcomes and production timelines, addressing the intricate equipment needs and stringent regulatory compliance of the industry. The predictive maintenance market caters to the unique challenges and regulatory requirements of healthcare and life sciences, contributing not only to enhanced equipment reliability but also to cost savings, efficient resource utilization, and compliance with industry standards. As these industries prioritize technological innovation, the predictive maintenance market is poised for substantial growth, offering tailored solutions that advance healthcare and life sciences practices, ultimately benefiting patient outcomes and scientific research.

North America Region is Expected to Witness Significant Growth Over the Forecast Period

In North America, the predictive maintenance market is experiencing significant growth and adoption across various industries. The region's advanced technological infrastructure and widespread digital transformation initiatives have created a fertile ground for the integration of predictive maintenance solutions. Industries such as manufacturing, energy, healthcare, and transportation in North America are increasingly recognizing the strategic advantages of predictive maintenance in optimizing operational efficiency and reducing downtime. The market is driven by the region's robust IT capabilities, a strong emphasis on data-driven decision-making, and the availability of skilled workforce adept in implementing advanced technologies. North American companies are leveraging predictive maintenance to monitor and enhance the performance of critical assets, improve overall equipment effectiveness, and achieve cost savings through optimized maintenance schedules. Additionally, the prevalence of cloud computing solutions in the region further facilitates the implementation of predictive maintenance, allowing organizations to leverage scalable and flexible platforms for data processing and analysis. As the demand for predictive maintenance continues to rise, North America remains at the forefront of adopting and innovating these technologies, contributing to the ongoing evolution of maintenance practices in the region.

Get Complete Analysis Of The Report - Download Free Sample PDF

Industry players are actively embracing a spectrum of strategic initiatives to fortify their positions in the competitive landscape. This includes forging partnerships, engaging in mergers and acquisitions, and collaborating with other firms to gain a strategic edge in the market. The objective is to leverage complementary strengths, share resources, and tap into synergies that enhance overall competitiveness. Additionally, companies are prioritizing the deployment of improved customer services as a key strategic initiative. Recognizing the pivotal role of customer satisfaction in sustaining and expanding market share, organizations are focusing on enhancing service quality, streamlining communication channels, and adopting innovative solutions to meet evolving customer expectations. These strategic maneuvers underscore a dynamic and proactive approach adopted by industry players to navigate the evolving business landscape and stay ahead in an increasingly competitive environment. Some of the prominent players operating in the global predictive maintenance market are:

Recent Development:

1) In June 2023, Accenture plc completed the acquisition of Nextira, a distinguished Amazon Web Services (AWS) premier partner specializing in harnessing AWS services for the delivery of predictive analytics, cloud-native innovations, and immersive experiences to its clientele. The integration of Nextira's expertise enhances the engineering capabilities of Accenture Cloud First, enabling the provision of comprehensive cloud solutions to clients. Nextira is recognized for its cloud-based services that incorporate state-of-the-art artificial intelligence, machine learning, engineering proficiency, and data analytics. These offerings empower clients to develop, design, launch, and optimize high-performance computing environments, aligning with Accenture's commitment to delivering cutting-edge solutions in the cloud computing landscape.

2) In November 2021, Toshiba Corporation (TOKYO: 6502) developed AI technology that automatically generated physical models for detecting equipment abnormalities and determining the causes of those abnormalities in social infrastructure equipment. The AI automatically generated a physical model that described the states and motion of a target device from measured time-series data. In addition, the AI not only showed abnormalities in equipment but also identified the causes of the occurrences of abnormalities based on physical phenomena, a task that had been challenging in the past. Toshiba's development positions the company as a technological leader in the field of predictive maintenance. This leadership can attract attention and interest from other businesses in Japan seeking advanced solutions for optimizing their maintenance practices. It could potentially drive increased adoption of predictive maintenance technologies across industries.

Q1. What was the Predictive Maintenance Market size in 2022?

As per Data Library Research the global predictive maintenance market was valued at USD 5.2 billion in 2022.

Q2. At what CAGR is the Predictive Maintenance market projected to grow within the forecast period?

Predictive Maintenance Market is expected to grow at a CAGR of 29.9% during the forecast period.

Q3. What are the factors on which the Predictive Maintenance market research is based on?

By Component, By Deployment Mode, By Organization Size, By Vertical Goverment and Geography are the factors on which the Predictive Maintenance market research is based.

Q4. Which region has the largest share of the Predictive Maintenance market? What are the largest region's market size and growth rate?

North America has the largest share of the market. For detailed insights on the largest region's market size and growth rate request a sample here.

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model