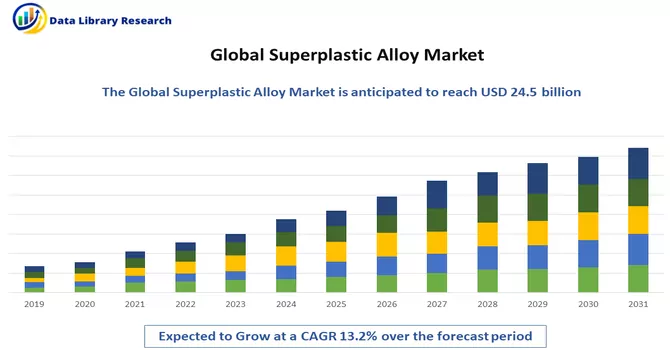

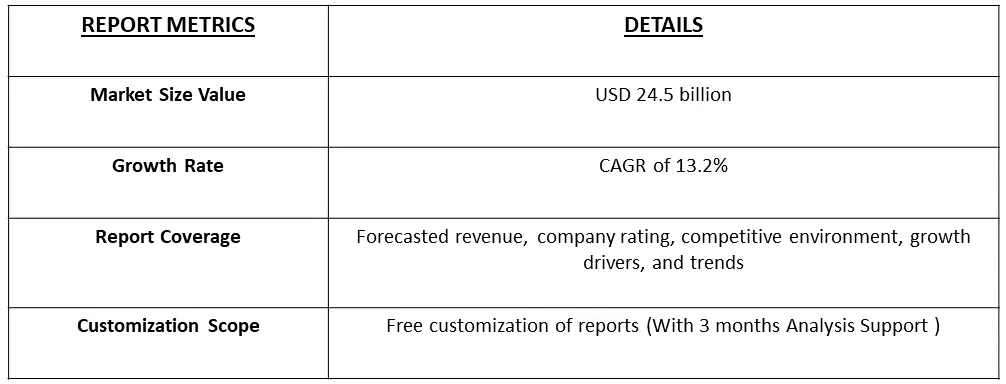

The Super Alloy market is currently valued at 24.5 billion in the year 2023 and is expected to register a CAGR of 13.2% over the forecast period, 2024-2031.

Get Complete Analysis Of The Report - Download Free Sample PDF

Superplastic alloys are advanced materials known for their exceptional ability to undergo significant plastic deformation at elevated temperatures without fracturing. These alloys exhibit unique mechanical properties, characterized by high elongation and strain rate sensitivity, enabling them to be easily shaped into intricate and complex forms through processes such as superplastic forming (SPF). Typically composed of fine-grained microstructures, superplastic alloys benefit from a combination of high temperature, low strain rate, and optimal grain size distribution, allowing for remarkable deformation capabilities while maintaining structural integrity. This class of materials finds applications in aerospace, automotive, and other industries where the production of intricate, lightweight, and high-strength components is crucial.

The market for superplastic alloys is driven by several key factors, including their unique combination of high-temperature deformability and enhanced mechanical properties. Industries such as aerospace and automotive are major contributors to the demand for superplastic alloys, as these materials enable the production of lightweight and intricately shaped components, leading to improved fuel efficiency and overall performance. The rising focus on fuel efficiency and stringent environmental regulations has heightened the demand for superplastic alloys in the automotive sector. Additionally, the aerospace industry benefits from these alloys in the fabrication of complex and lightweight structures, contributing to aircraft weight reduction and fuel savings. The expanding scope of applications in other sectors, such as medical devices and consumer electronics, further fuels the growth of the superplastic alloys market. Research and development efforts to enhance the material properties and reduce production costs also play a pivotal role in driving market expansion, as manufacturers seek to capitalize on the versatile applications of superplastic alloys across various industries.

The superplastic alloy market is propelled by several key drivers, primarily driven by the increasing demand for lightweight and high-performance materials in industries such as aerospace, automotive, and electronics. The unique ability of superplastic alloys to undergo extensive deformation at elevated temperatures without compromising structural integrity makes them invaluable for the production of complex and lightweight components, contributing to fuel efficiency improvements and overall performance enhancements. Furthermore, stringent regulations aimed at reducing carbon emissions and enhancing fuel efficiency in automotive and aerospace sectors are compelling manufacturers to adopt superplastic alloys, fostering market growth. On the contrary, the market faces certain restraints, including the high initial costs associated with the production and processing of superplastic alloys. Additionally, challenges related to scaling up production processes and achieving consistent material properties may hinder widespread adoption. Moreover, the limited awareness and understanding of superplastic alloys among end-users could pose a challenge to market expansion. Balancing these drivers and restraints is crucial for the sustained growth and market penetration of superplastic alloys across diverse industrial applications.

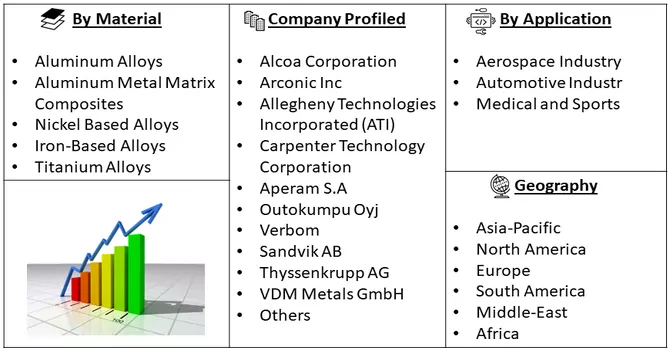

Market Segmentation: The Superplastic Alloys Market is Segmented by Substrate Material (Aluminum Alloys, Aluminum Metal Matrix Composites, Nickel Based Alloys, Iron-Based Alloys, and Titanium Alloys), Application (Aerospace Industry, Automotive Industry, Medical and Sports) ), and Geography (North America Europe Asia-Pacific Latin America and Middle-East and Africa). The report offers market forecasts and size in volume (billion units) and value (USD) for all the above segments.

For Detailed Market Segmentation - Download Free Sample PDF

Market Drivers:

Increasing Demand For Lightweight Materials With Enhanced Mechanical Properties In Industries Such As Aerospace, Automotive, And Electronics

The escalating demand for lightweight materials exhibiting enhanced mechanical properties has become a prominent trend across industries, particularly in aerospace, automotive, and electronics. This surge is driven by a collective emphasis on fuel efficiency, improved performance, and the need for advanced technologies. In the aerospace sector, lightweight materials contribute to fuel savings and increased payload capacity, while the automotive industry seeks to enhance fuel efficiency and overall vehicle performance. Similarly, in electronics, the quest for miniaturization and high-performance devices necessitates materials that are both lightweight and mechanically robust. This overarching trend underscores a pivotal shift towards innovative materials science and engineering solutions that cater to the evolving requirements of modern industries, where a premium is placed on materials that are not only lightweight but also boast superior mechanical properties.

Ongoing Research And Development Efforts To Improve Material Properties And Reduce Production Costs

Superplastic alloys, known for their extraordinary ability to undergo extensive deformation without fracturing, have become the focus of ongoing research and development efforts aimed at enhancing material properties and reducing production costs. These alloys, exemplified by characteristics like high elongation and low flow stress at elevated temperatures, offer remarkable formability, making them invaluable in various industrial applications. Current research endeavors are directed towards refining the microstructures of superplastic alloys to optimize their mechanical properties, tailoring them to meet specific industry requirements. Additionally, efforts are underway to develop innovative alloy compositions and fabrication techniques that not only enhance performance but also contribute to cost-effectiveness in the production process. The goal is to strike a balance between improved material characteristics and economical manufacturing, ensuring that superplastic alloys continue to play a pivotal role in industries such as aerospace, automotive, and manufacturing where complex shapes and lightweight structures are highly desirable. As research progresses, advancements in superplastic alloys hold the promise of fostering innovation and efficiency across diverse industrial applications.

Market Restraints:

Limited awareness and understanding of superplastic alloys

The potential impediment to the growth of the superplastic alloy market lies in the limited awareness and understanding surrounding these exceptional materials. Despite their remarkable characteristics such as high formability and the ability to undergo extensive deformation, the broader industrial community may not be fully aware of the advantages and applications of superplastic alloys. This lack of awareness can lead to underutilization of these alloys, hindering their widespread adoption across various industries. Educational efforts and outreach initiatives are crucial to bridge this knowledge gap and enhance the understanding of the unique properties and benefits offered by superplastic alloys. As industries increasingly seek advanced materials for applications demanding intricate shapes and lightweight structures, overcoming the limited awareness barrier is essential for unlocking the full potential of superplastic alloys and ensuring their integration into diverse sectors such as aerospace, automotive, and manufacturing. Efforts in education and awareness campaigns will be pivotal in driving the growth and acceptance of superplastic alloys within the industrial landscape.

The global demand for superplastic alloys faced notable challenges amidst the COVID-19 pandemic, as disruptions in supply chains and reduced industrial activities impacted the manufacturing sector. The pandemic-induced economic uncertainties and logistical constraints affected both production and adoption of superplastic alloys in various industries. While the unique properties of superplastic alloys, such as high formability, make them promising for applications in aerospace, automotive, and manufacturing, the industry faced delays and setbacks due to pandemic-related restrictions. However, as economies recover and industries regain momentum, there is potential for a renewed focus on the development and utilization of superplastic alloys, especially as their benefits align with the ongoing emphasis on lightweight materials and advanced engineering solutions across diverse sectors. The long-term impact of the pandemic underscores the resilience and adaptability needed to navigate challenges in the superplastic alloy market and to harness their full potential in the post-pandemic industrial landscape.

Segmental Analysis:

Titanium Alloys Segment is Expected to Witness Significant Growth Over the Forecast Period

Titanium alloys, known for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, have become integral in aerospace, medical, and industrial applications. These alloys, derived from the lightweight and durable metal titanium, are favored for their ability to withstand extreme conditions and offer superior performance in demanding environments. Simultaneously, superplastic alloys, characterized by their remarkable capacity for extensive deformation without fracturing, have garnered attention for their unique formability and versatility. Particularly useful in aerospace and manufacturing, superplastic alloys allow for the production of intricate and complex shapes, contributing to advancements in lightweight structures and fuel-efficient transportation. While titanium alloys excel in providing high strength and corrosion resistance, superplastic alloys offer a distinctive advantage in shaping and forming processes. The combination of these alloys can result in innovative materials solutions, showcasing the potential for synergies between the high-strength properties of titanium alloys and the extraordinary formability of superplastic alloys, fostering advancements in various industries requiring lightweight, durable, and intricately designed components. As research and development efforts continue, the collaborative utilization of titanium alloys and superplastic alloys holds promise for driving technological innovation across diverse applications.

Aerospace Industry Segment is Expected to Witness Significant Growth Over the Forecast Period

In the aerospace industry, superplastic alloys play a crucial role as transformative materials. Renowned for their remarkable ability to undergo extensive deformation without fracturing, these alloys offer a solution to the industry's demand for lightweight materials with superior mechanical properties. Superplastic alloys, utilized in processes like superplastic forming and diffusion bonding, enable the production of intricate and lightweight components, contributing to enhanced fuel efficiency and overall aircraft performance. This unique formability facilitates the creation of complex shapes and structures, aligning seamlessly with the aerospace sector's need for precision and innovation. As the industry continues to prioritize advancements in aircraft design and manufacturing, the synergistic relationship between the aerospace industry and superplastic alloys is poised to drive breakthroughs, paving the way for more efficient, durable, and technologically advanced aerospace systems.

Asia Pacific Segment is Expected to Witness Significant Growth Over the Forecast Period

In the Asia Pacific region, the utilization of superplastic alloys is gaining prominence as industries across the spectrum increasingly recognize the transformative potential of these materials. Superplastic alloys, known for their exceptional formability without fracturing, align with the diverse needs of manufacturing, aerospace, and automotive sectors prevalent in the region. The Asia Pacific's burgeoning industrial landscape, marked by rapid technological advancements and a focus on lightweight, high-performance materials, makes superplastic alloys particularly relevant. In manufacturing, these alloys find application in shaping intricate and complex components with precision, offering a competitive edge in industries demanding intricate designs. The automotive sector benefits from superplastic alloys in the production of lightweight and structurally advanced components, contributing to fuel efficiency and overall vehicle performance. Moreover, the aerospace industry in the Asia Pacific region is leveraging superplastic alloys for their ability to create complex structures, enhancing aircraft design and fuel economy. As research and development efforts in the Asia Pacific region continue to drive innovation, the adoption of superplastic alloys is expected to grow, offering solutions to the evolving needs of diverse industries. The symbiosis between the Asia Pacific's dynamic industrial landscape and the transformative capabilities of superplastic alloys positions these materials as key contributors to the region's technological advancements and economic growth.

Get Complete Analysis Of The Report - Download Free Sample PDF

The analyzed market exhibits a high degree of fragmentation, primarily attributable to the presence of numerous players operating on both a global and regional scale. The competitive landscape is characterized by a diverse array of companies, each contributing to the overall market dynamics. This fragmentation arises from the existence of specialized solution providers, established industry players, and emerging entrants, all vying for market share. The diversity in market participants is underscored by the adoption of various strategies aimed at expanding company presence. On a global scale, companies within the studied market are strategically positioning themselves through aggressive expansion initiatives. This often involves entering new geographical regions, targeting untapped markets, and establishing a robust global footprint. The pursuit of global expansion is driven by the recognition of diverse market opportunities and the desire to capitalize on emerging trends and demands across different regions. Simultaneously, at the regional level, companies are tailoring their approaches to align with local market dynamics. Regional players are leveraging their understanding of specific market nuances, regulatory environments, and consumer preferences to gain a competitive edge. This regional focus allows companies to cater to the unique needs of local clientele, fostering stronger market penetration. To navigate the complexities of the fragmented market, companies are implementing a range of strategies. These strategies include investments in research and development to stay at the forefront of technological advancements, mergers and acquisitions to consolidate market share, strategic partnerships for synergies, and innovation to differentiate products and services. The adoption of such multifaceted strategies reflects the competitive nature of the market, with participants continually seeking avenues for growth and sustainability. In essence, the high fragmentation in the studied market not only signifies the diversity of players but also underscores the dynamism and competitiveness that drive ongoing strategic maneuvers. As companies explore various avenues for expansion, the market continues to evolve, presenting both challenges and opportunities for industry stakeholders. Some of the major players working in this market segment are:

Recent Development:

1) In October 2023: Telespazio Germany and Reflex Aerospace entered into a collaborative agreement to jointly provide a comprehensive end-to-end satellite solution. This strategic partnership leverages the specialized expertise of each company, combining Reflex Aerospace's proficiency in developing payload-specific satellites with Telespazio's excellence in ground segment services and mission control capabilities, delivered through its EASE-Rise platform. This collaboration aims to deliver a seamless and integrated satellite solution, optimizing the capabilities of both entities. While the provided information does not specifically mention the use of superplastic alloys in this context, it's important to note that advancements in satellite technology often involve the integration of lightweight and high-performance materials, and the collaboration between Telespazio Germany and Reflex Aerospace could potentially contribute to the broader technological developments, potentially including materials like superplastic alloys, that enhance the efficiency and capabilities of satellite systems.

2) In the year 2023, research conducted by the University of Washington highlighted that Aluminium AA5083 represents a non-heat-treatable aluminum alloy known for its outstanding cold formability and the ability to attain moderate levels of superplasticity. This cost-effective alloy demonstrates reasonable environmental resistance and possesses commendable mechanical properties, rendering it well-suited for applications in the aerospace, marine, and automotive industries.

Q1. What was the Superplastic Alloy Market size in 2023?

As per Data Library Research the Super Alloy market is currently valued at 24.5 billion in the year 2023.

Q2. What is the Growth Rate of the Super Alloy market?

Super Alloy market is expected to register a CAGR of 13.2% over the forecast period.

Q3. What segments are covered in the Super Alloy market Report?

By Substrate Material, By Application and Geography these segments are covered in the Super Alloy market Report.

Q4. Who are the key players in Super Alloy market?

Some key players operating in the market include

Data Library Research are conducted by industry experts who offer insight on industry structure, market segmentations technology assessment and competitive landscape (CL), and penetration, as well as on emerging trends. Their analysis is based on primary interviews (~ 80%) and secondary research (~ 20%) as well as years of professional expertise in their respective industries. Adding to this, by analysing historical trends and current market positions, our analysts predict where the market will be headed for the next five years. Furthermore, the varying trends of segment & categories geographically presented are also studied and the estimated based on the primary & secondary research.

In this particular report from the supply side Data Library Research has conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and SOFT) of the companies that active & prominent as well as the midsized organization

FIGURE 1: DLR RESEARH PROCESS

Extensive primary research was conducted to gain a deeper insight of the market and industry performance. The analysis is based on both primary and secondary research as well as years of professional expertise in the respective industries.

In addition to analysing current and historical trends, our analysts predict where the market is headed over the next five years.

It varies by segment for these categories geographically presented in the list of market tables. Speaking about this particular report we have conducted primary surveys (interviews) with the key level executives (VP, CEO’s, Marketing Director, Business Development Manager and many more) of the major players active in the market.

Secondary ResearchSecondary research was mainly used to collect and identify information useful for the extensive, technical, market-oriented, and Friend’s study of the Global Extra Neutral Alcohol. It was also used to obtain key information about major players, market classification and segmentation according to the industry trends, geographical markets, and developments related to the market and technology perspectives. For this study, analysts have gathered information from various credible sources, such as annual reports, sec filings, journals, white papers, SOFT presentations, and company web sites.

Market Size EstimationBoth, top-down and bottom-up approaches were used to estimate and validate the size of the Global market and to estimate the size of various other dependent submarkets in the overall Extra Neutral Alcohol. The key players in the market were identified through secondary research and their market contributions in the respective geographies were determined through primary and secondary research.

Forecast Model